Silicone Rubber Membrane For Solar Laminating Machine - 3S Solar Laminator

CASIS – Asia's leading supplier for specialty silicone rubber sheets for solar panel manufacture in the renewable energy market.

Silicone Rubber Sheet for Solar Module Laminator. Although also called diaphragms, sheets, or membranes, the solar panel industry tends to use the term membrane.

Product description and advantages

-

Diaphragms for PV module manufacture

-

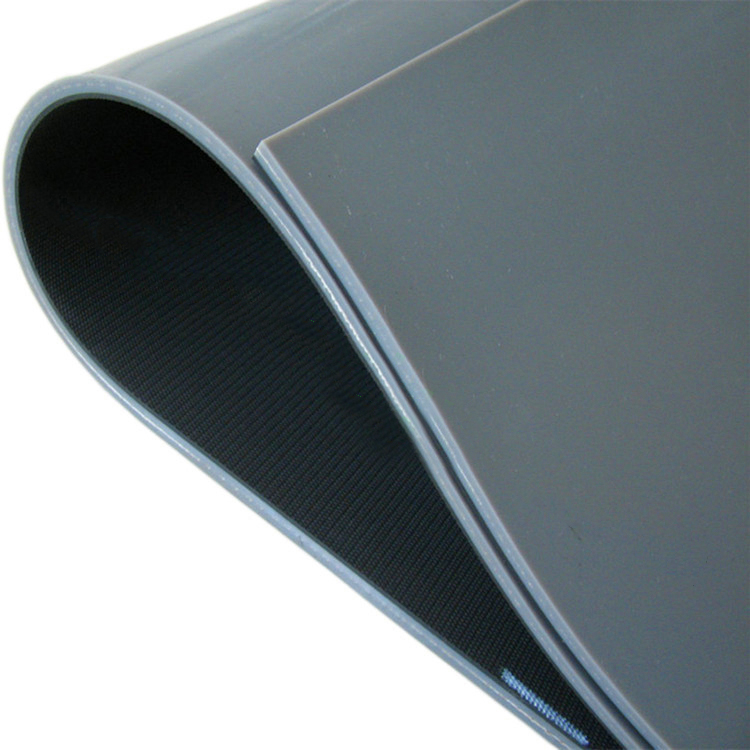

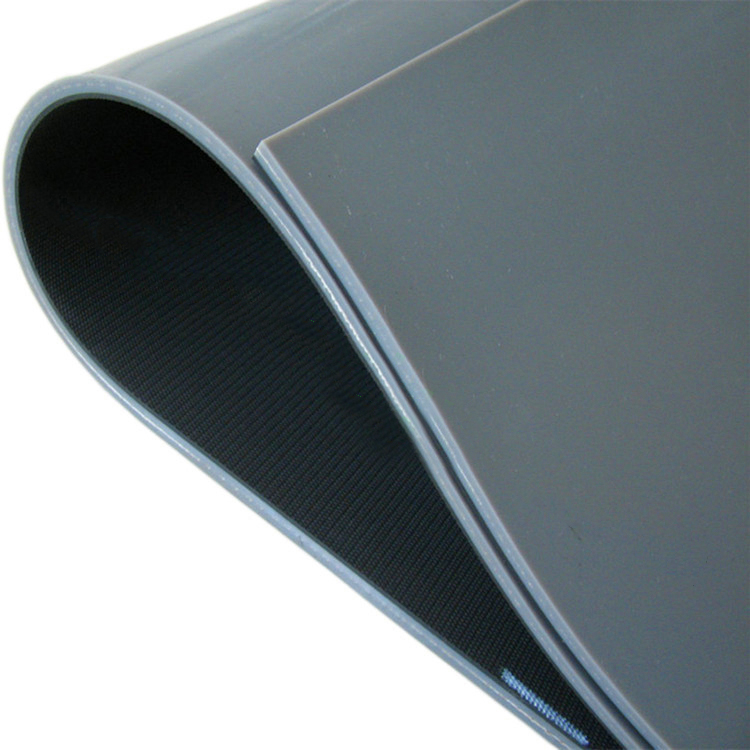

Special covering layer (black) on silicone backing (grey)

-

Bond of the two layers cannot be separated mechanically

-

Black covering layer is resistant to decomposing outgassing during lamination process

-

Durability results in longer machine running times and thus shorter set-up times

-

Constant quality thanks to quality management

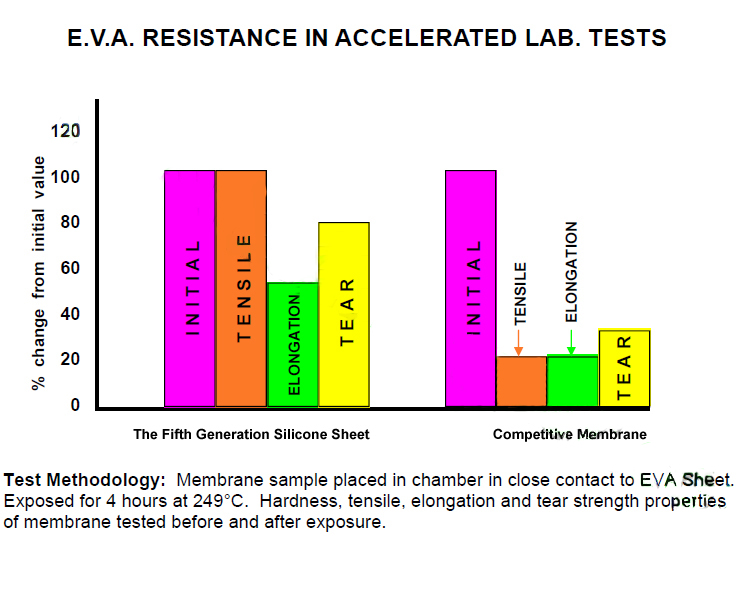

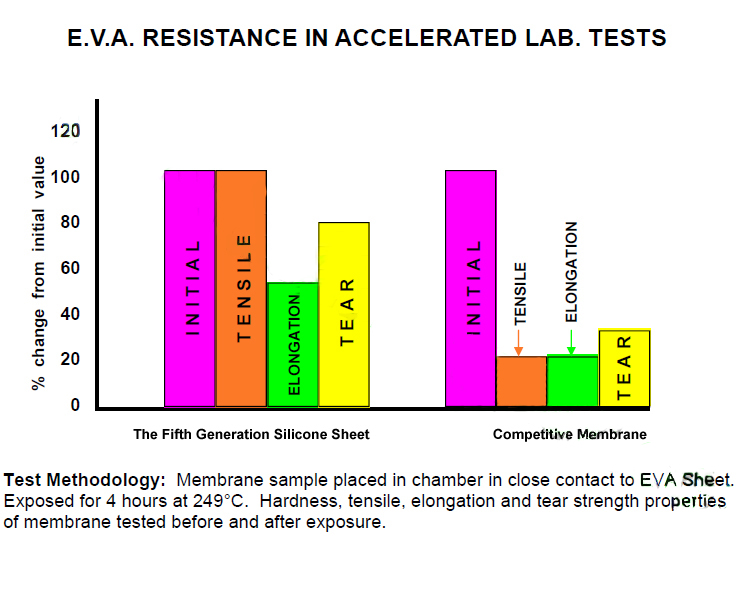

KS-EXR668 is our fifth generation silicone sheet series, it’s a specially developed membrane consisting of a silicone backing material and a unique covering layer. This covering layer is extremely resistant to outgassing and related decomposing processes of EVA films. This makes Lamination particularly durable and increases your machine running times.

Corrosive attack on Silicone Sheets

World-wide producers of thin film and crystalline solar panels face corrosive attacks on Silicone Sheets used on lamination equipment.

During the lamination / encapsulation process of EVA volatile outgassing occurs. Outgassing refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Sheets. This corrosion manifests itself in surface degradation (cracks) + excessive stretching and sagging.

KS-EXR668 series Silicone Sheet is a hybrid material that resists the deterioration caused by EVA outgassing. In addition it is a really tough material with both tensile strength and tear resistance higher than traditional Membranes materials.

KS-EXR668 series Silicone Sheet has very tight elongation features – resistant to excessive stretching and sagging. Customers’ feedback indicates that our silicone sheets may give up to 50% longer life than some traditional Diaphragm materials – obviously dependent upon type of module, encapsulant and conditions.

Area of application

Solar Photovoltaic Laminators

Solar Photovoltaic Laminators

|

|

Backing Material

(Buffering Surface) |

Covering Layer

(Eva resistant working surface) |

Test Method |

|

Material |

Silicone – Gray |

Special layer – Black

(Fluorine Rubber) |

- |

|

Hardness |

62±2 Shore A |

76±2 Shore A |

ASTM D2240

DIN 53505 |

|

Density/Spe.Weight |

1.25±0.05 g/qm3 |

1.90±0.05 g/qm3 |

ISO 2781

BS 903 A5 |

|

Tensile Strength |

9Mpa |

16Mpa |

BSISO 37

DIN 53505 die S1

ASTM D412 Die C |

|

Elongation at tear |

700% |

200% |

BSISO 37

DIN 53505 die S1

ASTM D412 Die C |

|

Resilience |

25% |

8% |

ASTM D1054 / D2632 |

|

Tear Strength |

67.7 N/mm |

16.3 N/mm |

BSISO 34-1 Method C

ASTM D 624 B |

|

Module 100% |

1.5 N/mm2 |

- |

- |

|

Module 200% |

2.2 N/mm2 |

- |

- |

|

Module 300% |

2.9 N/mm2 |

- |

- |

|

Max. temperature |

250℃ |

- |

- |

Standard dimensions

|

Width |

Max up to 3780mm |

|

|

|

|

Material thickness |

4 mm or 3mm |

|

|

|

|

|

Fabrication even beyond the standard width |

The following dimensions are from our customers' requirements:

|

Corresponding Standards Country |

Commonly Used Size |

|

The United State |

3600 x 1900 x 4mm |

|

Bangladesh |

3600 x 1660 x 3mm |

|

Philippines |

3500 x 1600 x 4mm |

|

Switzerland |

3300 x 1900 x 3mm |

|

Austria |

3290 x 1550 x 3mm |

|

Brazil |

3100 x 1760 x 4mm |

|

UK |

3067 x 1660 x 3mm |

|

The United State |

3048 x 1660 x 4mm |

|

Mexico |

3000 x 1660 x 4mm |

|

India |

2350 x 1370 x 4mm |

|

India |

1970 x 1270 x 4mm |

|

India |

6550 x 2550 x 4mm |

|

Korea |

5200 x 2600 x 4mm |

|

Germany |

4450 x 3050 x 4mm |

Silicone Membranes FAQs

What’s the best membrane for our application?

This is a big question and really best discussed together on the phone. Determining factors would include your type of encapsulant, composition of the modules, size of the modules, and type of laminator.

How long should a diaphragm last?

This also depends on your encapsulant and type of module. Give us a call to talk about your product and processes to determine what you should be getting from your membrane.

What can we do to extend the life of our membrane?

Consider protecting it with a layer of PTFE sheet between the modules and the membrane. We have several options for this. And if you’re encapsulating with EVA, we should discuss the fifth generation KS-EXR668 Silicone membrane that is resistant to the outgassing from the EVA. The Fifth Generation KS-EXR668 option may give you far better life than your current membrane.