HIGH-END VITON SERIES

We will also provide high-end material rubber series to meet the most demanding industrial applications.

Viton® material

FKM Viton® rubber, also known as Fluorocarbon rubber, is known for its excellent oil and air resistance properties. FKM Viton rubber has excellent resistance to high temperatures, ozone, oxygen, mineral oil, synthetic hydraulic fluids, fuels, aromatics and many organic solvents and chemicals. Extreme temperature and nearly legendary oil and fuel resistance makes FKM Viton rubber the choice for some of the toughest applications.

Depending on the grade, FKM Viton® rubber can operate continuously in excess of 200°C / 392 F° with intermittent spikes as high as 300°C / 570°F. Proper selection and compounding can provide low temperature resistance as well. It also possesses low gas permeability, low compression set and good mechanical properties.

FKM Viton® rubber is commonly used in aircraft engines, automotive fuel handling systems and high chemical exposure applications. FKM Viton® rubber is typically good with most chemicals and acids, but it’s good practice to check your Chemical Resistance Guide.

FKM Viton® rubber is attacked by amines, strong alkalis and many Freon’s. It also has limited resistance to steam, hot water, methanol, ketones, low molecular weight esters and nitro containing compounds like Skydrol, synthetic hydraulic fluids, certain esters and ethers.

You may occasionally see the following names from major polymer manufacturers: Dai-El®, Fluorel®, Technoflon®, Viton®

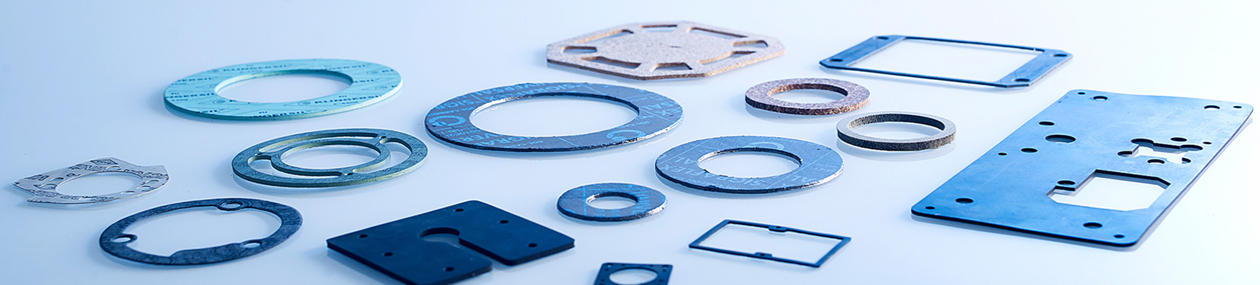

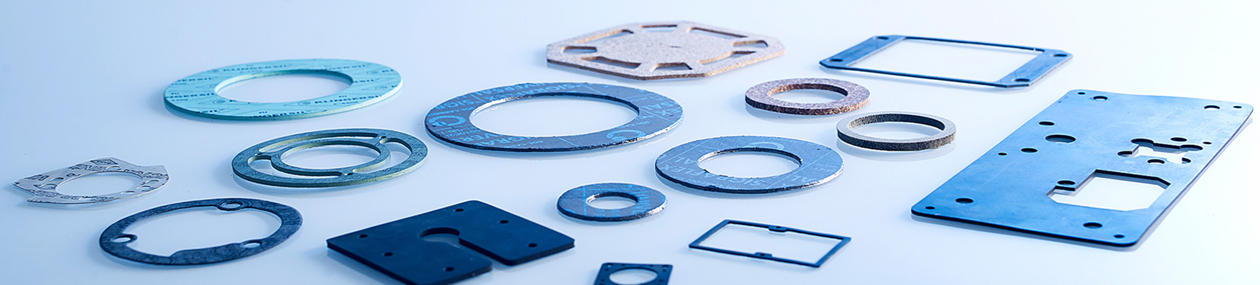

Viton® sheeting

Viton® sheeting

Known either as fluoroelastomer or FKM, is highly appreciated for the most demanding industrial applications as it has the highest resistance to hydrocarbons, acids, alkalis and even oxidants, and its mechanical properties remain intact at temperatures of up to 250ºC.

Different types of optimised Viton® sheeting exist according to the final use required, and there is a demand for it in heavy industries such as oil and petroleum refineries, steel works and chemical plants, and also in industries with special requirements such as the food industry.

Properties

Properties

-

FKM's are serviceable in continuous heat of up to 250º C and intermittent heat of up to 300º C.

-

Satisfactory resistance to low temperatures of typically -20º C and - 40º C by use of special grades.

-

FKM's exhibit good flame resistance and are usually self extinguishing upon removal of flame source.

-

All FKM's have excellent resistance to oxygen, ozone and natural weathering.

-

FKM compounds have outstanding resistance to compression, especially at elevated temperatures.

-

Resistance to chemicals; amongst all synthetic rubbers FKM's are the most resistant to many of the solvents and chemicals, giving long service where other materials do not.

-

Excellent resistance against hydrocarbons, aliphatics, aromatic and chlorinated chemicals.

-

Good resistance to acids and alkali's including oxidants. Poor performance against ethers, ketones, and bases.

Product Description

Product Description

Viton

® fluoroelastomer is well known for its excellent resistance to aggressive fuels and chemicals, high heat (400°F/200°C), abrasions and cuts. Viton

® also offers superb mechanical properties and can meet many performance specifications. Particularly valued for its excellent heat stability and resistance to aggressive fuels and chemicals, Viton

® is the most specified fluoroelastomer for fuel system seals and hoses, O-rings, shaft seals, expansion joints and gaskets. Viton

® rubber is good for a broad spectrum of applications in the automotive, chemical processing and industrial markets, including:

-

Chemical resistant gaskets and Viton® seals

-

High temperature Viton® gaskets

-

O-rings

-

Lathe-cut Viton® gaskets and seals

Viton

® is a registered trademark of DuPont Performance Elastomers.

Viton

® rubber, a specific fluoroelastomer polymer (FPM), was introduced into the aerospace industry in 1957 to fulfill its needs for a high-performance elastomer. Following its introduction, the usage of Viton

® spread quickly to other industries including the automotive, appliance, chemical and fluid power industries. Viton

® has a strong reputation as a high performance elastomer in very hot and extremely corrosive environments.

Well known for its excellent heat resistance properties (400°F/200°C), Viton® is the most specified fluoroelastomer available for:

Fuel system seals & hoses

O-rings

Shaft seals

Expansion joints and gaskets

Because it can extend the thermal resistance of mid-performance elastomers, Viton® has been used extensively in aggressive automobile fuel systems as well as aircraft and chemical processing environments. Viton® was also the first fluoroelastomer to obtain worldwide ISO 9000 registration.

As a product of DuPont elastomers, Viton® rubber can be processed to meet the performance requirements of many automotive, chemical processing and various other industrial applications.

Viton® Material Properties

|

Common Names |

Viton®, Fluro Elastomer, FKM |

|

ASTM D-2000 Classification |

HK |

|

Military (MIL-STD 417) |

MIL — R — 25897 & MIL — R - 83248 |

|

Chemical Definition |

Fluorinated Hydrocarbon |

|

General Characteristics |

|

|

Durometer Range (Shore A) |

60-90 |

|

Tensile Range (P.S.I) |

500-2000 |

|

Elongation (Max %) |

300 |

|

Compression Set |

Good |

|

Resilience — Rebound |

Fair |

|

Abrasion Resistance |

Good |

|

Tear Resistance |

Good |

|

Solvent Resistance |

Excellent |

|

Oil Resistance |

Excellent |

|

Low Temperature Usage (F°) |

+10° to -10° |

|

High Temperature Usage (F°) |

400° to 600° |

|

Aging Weather — Sunlight |

Excellent |

|

Adhesion to Metals |

Good |

Applications

Applications

Viton's® performance reliability under extreme exposure conditions makes it an attractive material to use in many demanding applications. Such performance is a major requisite for parts in the aerospace and aircraft service industries. For example, Viton®O-rings with a service temp. of -45°C to +275°C will also resist the effects of thermal cycling, which are encountered during the rapid ascent and descent of aircraft from the stratosphere.

The high performance properties of Viton® can be seen in many aircraft components including:

-

Radial lip seals used in pumps

-

Manifold gaskets

-

Cap-seals

-

-

T-Seals

-

O-rings used in line fittings, connectors, valves, pumps, and oil reservoirs

-

Siphon hoses

Additionally, Viton® is the polymer of choice for many of today's advanced fuel and engine systems. Viton's® effectiveness to perform against extremes of heat, chemicals, and fuel mixtures allows it to be used for fuel seals, quick-connect O-rings, head & intake manifold gaskets, fuel injection seals, and advanced fuel hose components.

Advantages of Viton (Temperature Capabilities)

Advantages of Viton (Temperature Capabilities)

Many applications require rubber parts to be stressed by accidental temperature excursions as well as increased operating temperatures to allow for increases in production. In certain instances, Viton® has been known to perform continuously at 204°C and even after short excursions to 315°C. Certain grades of Viton® rubber can also perform equally well in temperatures as low as -40°C.

Resistance to aggressive fluids

Viton® is well known for its ability to perform in a wide range of environments where aggressive fluids are present. By incorporating FPM material, systems can tolerate changes in fluids, allowing for more versatility in a broader range of applications.

Process Purity and Integrity

If FDA compliance is necessary, Timco Rubber has access to certain types of Viton materials that meet FDA requirements for food and pharmaceutical applications.

Compliant with tougher Regulations

As environmental regulations have raised the stakes against emissions, spills and leaks, Viton high performance seals have filled the gap where other elastomers fall short.

Broad Chemical Compatibility

A Quick Comparison

Broad Chemical Compatibility

A Quick Comparison

Viton materials are compatible with many important chemicals. Comparing the capabilities of other elastomers to FPM materials like Viton® can be helpful when starting your project or considering a change in materials to increase reliability or to accommodate more severe operating conditions.

|

Comparison of elastomer properties1 |

|

Common Name |

Neoprene |

Ethylene Propylene |

Nitrile |

Silicone |

Fluoro-silicone |

Viton (FPM) |

|

Chemical Compatibility |

|

Lubricating and fuel oils |

G |

NR |

E |

NR |

E |

E |

|

Hydraulic oils |

G |

NR |

E |

G,F |

E |

E |

|

Fireproof hydraulic fluids |

G |

E |

F |

F |

NR |

NR |

|

Vegetable oils, animal fats |

G,F |

G,F |

E |

E,F |

E |

E |

|

Gasoline (high octane) |

F,NR |

NR |

E,G |

NR |

E |

E |

|

Kerosene |

G |

NR |

E |

NR |

E |

E |

|

Aromatic hydrocarbons |

NR |

NR |

G,NR |

NR |

G,F |

E |

|

Aliphatic hydrocarbons |

G |

NR |

E |

NR |

G,F |

E |

|

Alcohols |

E |

G |

E |

G |

E,G |

E |

|

Ketones |

F,NR |

E |

NR |

NR |

NR |

NR |

|

Halogenated solvents |

NR |

NR |

NR |

NR |

E,G |

G |

|

Water (>80°C) |

F |

E |

E |

E,F |

E |

E |

|

Concentrated acids |

NR |

NR |

NR |

NR |

F |

E,G |

|

Diluted acids |

G,F |

G |

F,NR |

NR |

F |

E |

|

Alkalis |

E,G |

E |

G |

E,G |

G,F |

NR |

1Data is the published results of tests at DuPont Performance Elastomers and industry sources

Data is presented for use only as a general guide and should not be the sole basis for design decisions.

Key: E=Excellent, G=Good, F=Fair, NR=Not Recommended

All of our Fluoroelastomer (FKM) products are manufactured with 100% virgin FKM Fluoroelastomer polymer sourced from the world's leading manufacturers - 3M™ and Chemours™ (formerly DuPont).

Fluoroelastomers were originally introduced over 50 years ago to meet the needs of the aerospace industry for a high-performance elastomer. Since then, the use of fluoroelastomers has spread quickly to many other industries, including the automotive, oil, fluid power, appliance and chemical industries and has developed a reputation for its outstanding performance in very hot and extremely corrosive environments.

Fluoroelastomers are particularly valued for their excellent heat stability (200°C) and resistance to aggressive fuels and chemicals.

What is Fluoro-elastomer material?

What is Fluoro-elastomer material?

Fluoro-elastomer is more commonly known by the trade name Viton®, a brand name which has become synonymous with the material, therefore, throughout our site, fluoro-elastomer may be referred to as Viton® or FKM rubber. The commercial Viton sheeting available to purchase from us, at Martin’s Rubber, is manufactured using genuine Dupont Viton® compound. Viton®, FMP, or FKM rubber is a fluoroelastomer, which means that Viton material is a high performance synthetic rubber with exceptional properties, particularly when working with aggressive chemicals and fuels. FKM material is also known for having a very high temperature resistance.

Where is Viton Sheet used?

Viton sheet and Viton rubber strips are commonly used in environments whereby explosive gases are a primary concern. It is for this reason that FKM material is commonly known as the material of choice within the oil and gas industry.

Viton Sheet Properties

Viton Sheet Properties

Before selecting a rubber sheet material, it is important to thoroughly evaluate the qualities of each material, in order to understand and be able to predict how the material will act under certain circumstances. Some Viton sheet properties that should be considered before purchase include the thickness, hardness and temperature resistance of FKM rubber. Below, we have detailed some Viton sheet properties to help you decide if FKM material is the ideal product to suit your specific application.

Viton Sheet Thickness & Tolerance

Viton® sheeting is usually stocked in thicknesses from 1mm to 3mm. However, Viton sheet is available in thicknesses of up to 10mm. The commercial FKM sheeting product is 70° hardness and is supplied in rolls of up to 1.2m wide.

Temperature Range for Viton Rubber

FKM sheet is able to operate at extremely high and low temperatures. In fact, FKM rubber is able to withstand temperatures from as low as -10°C through to +250°C. It is due to Viton’s temperature range that Viton sheet is thought to be a highly resilient and flexible material.