Materials history

Silicone rubber was the result of the efforts of various chemical companies across the world searching for a material that could handle extreme temperatures. The first appearance of the silicone elastomer came in 1943. It was made available for mass consumption worldwide in 1947. In the decades since its debut, silicone material has been popular for use in automotive, food handling, electronic, photovoltaic, glass, woodworking, medical, and construction applications. This is primarily because silicone rubber has a broad working temperature range that allows it to handle high and low extremes. Silicone products also exhibit good levels of weather and chemical resistance, making them ideal for a host of outdoor and industrial uses. The strengths of this synthetic elastomer are hard to ignore.

Properties

Properties

Silicone rubber offers good resistance to extreme temperatures, being able to operate normally from −100 to 300 °C (−148 to 572 °F). Some properties such as elongation, creep, cyclic flexing, tear strength, compression set, dielectric strength (at high voltage), thermal conductivity, fire resistance and in some cases tensile strength can be—at extreme temperatures—far superior to organic rubbers in general, although a few of these properties are still lower than for some specialty materials. Silicone rubber is a material of choice in industry when retention of initial shape and mechanical strength are desired under heavy thermal stress or sub-zero temperatures. Organic rubber has a carbon-to-carbon backbone which can leave it susceptible to ozone, UV, heat and other ageing factors that silicone rubber can withstand well. This makes silicone rubber one of the elastomers of choice in many extreme environments.Silicone rubber is highly inert and does not react with most chemicals. Due to its inertness, it is used in many medical applications including medical implants. It is biocompatible, hypoallergenic, which makes it suitable for baby care products, and food contact in general. Silicone rubber is a reliable solution (as opposed to rubber and thermoplastic elastomers) for migration or interaction problems between the main active ingredients. Its chemical stability prevents it from affecting any substrate it is in contact with (skin, water, blood, active ingredients, etc.)

Special grades

Special grades

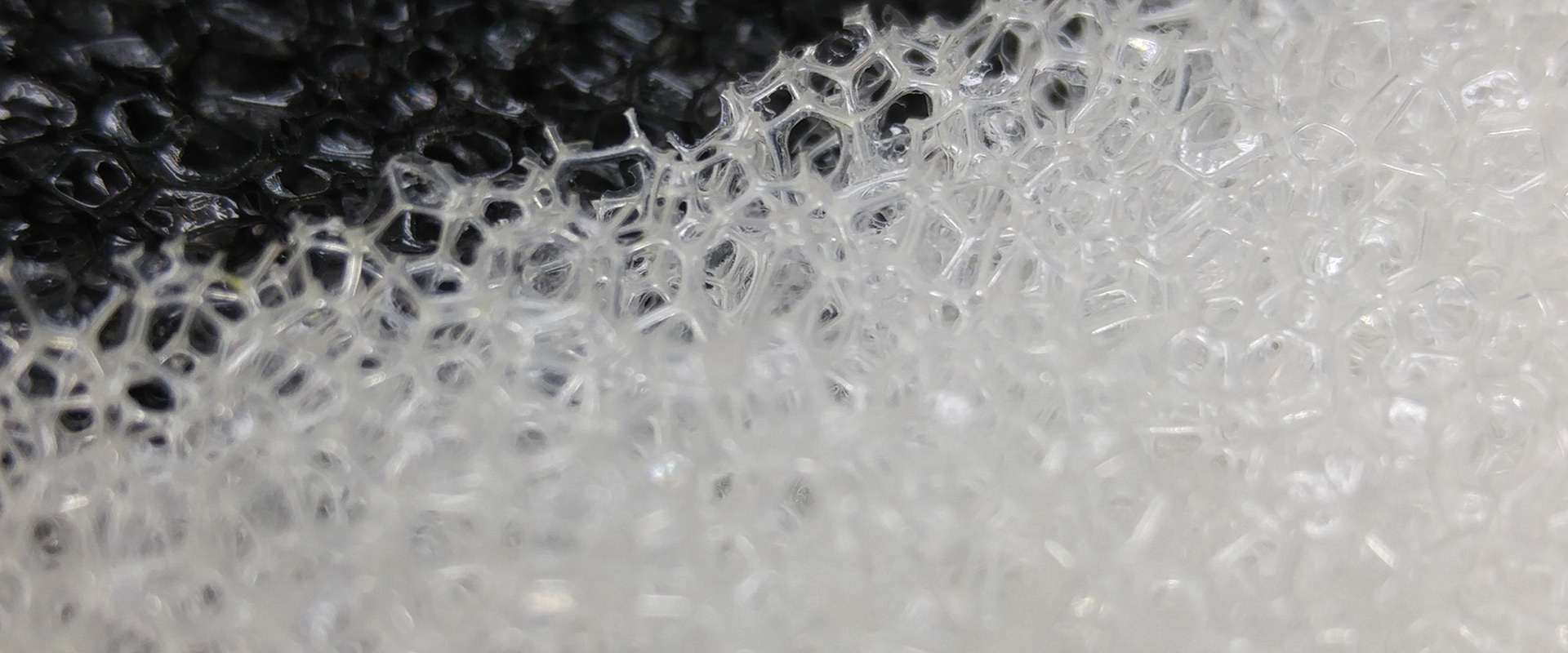

There are many special grades and forms of silicone rubber, including: steam resistant, metal detectable, high tear strength, extreme high temperature, extreme low temperature, electrically conductive, chemical/oil/acid/gas resistant, low smoke emitting, and flame-retardant. A variety of fillers can be used in silicone rubber, although most are non-reinforcing and lower the tensile strength. Silicone rubber is available in a range or hardness levels, expressed as Shore A or IRHD between 10 and 100, the higher number being the harder compound. It is also available in virtually any colour, and can be colour matched.

Applications

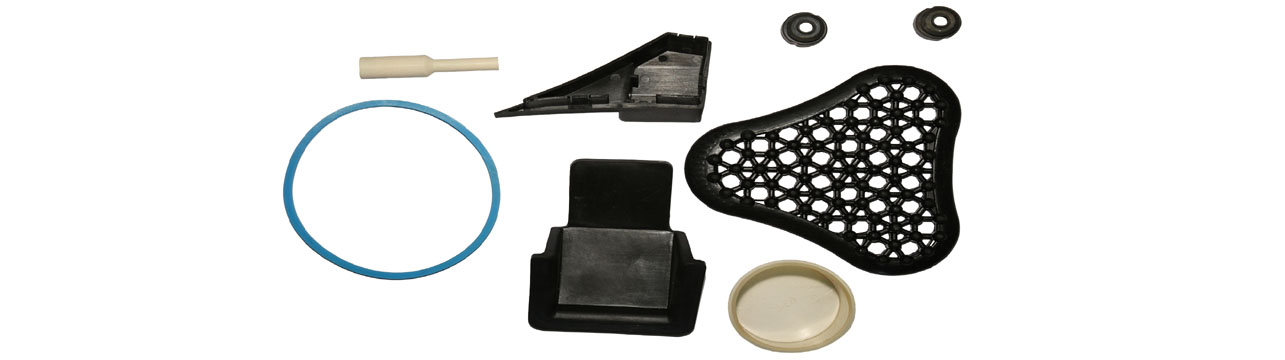

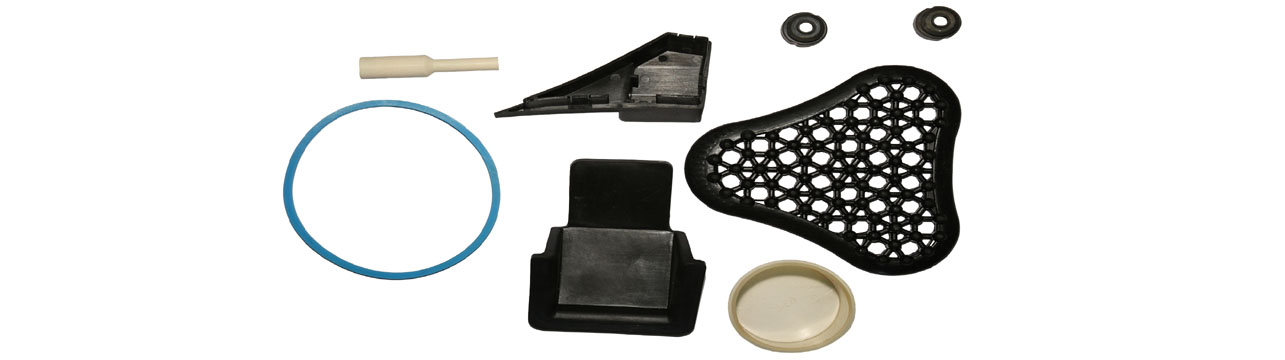

Once mixed and coloured, silicone rubber can be extruded into tubes, strips, solid cord or custom profiles according to the size specifications of the manufacturer. Cord can be joined to make O-rings and extruded profiles can be joined to make seals. Silicone rubber can be moulded into custom shapes and designs. Manufacturers work to set industry tolerances when extruding, cutting or joining silicone rubber profiles. In the UK this is BS 3734, for extrusions the tightest level is E1 and the widest is E3.

Becoming more and more common at the consumer level, silicone rubber products can be found in every room of a typical home. It is used in automotive applications, many cooking, new energy resources, glass, woodworking, baking, and food storage products, apparel including undergarments, sportswear, and footwear, electronics, to home repair and hardware, and a host of unseen applications.With the addition of carbon or another conductive substance as a powdered filler, silicone rubber can be made electrically conductive while retaining most of its other mechanical properties. As such it is used for flexible contacts which close on being pressed, used in many devices such as computer keyboards and remote control handsets.

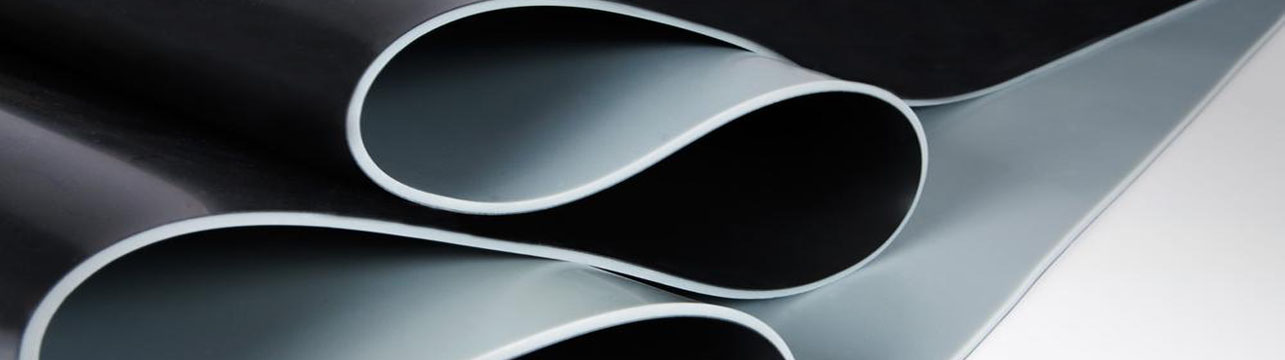

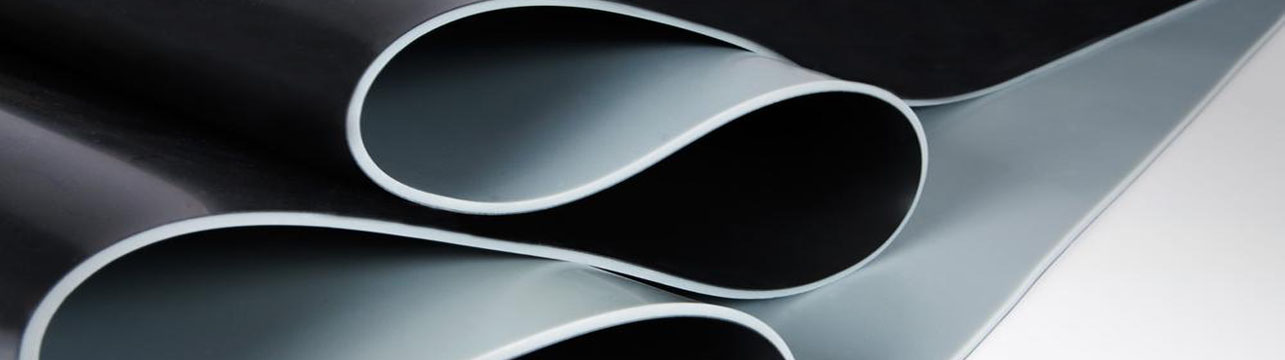

CASIS offers common silicone sheets in commercial grade, premium grade, translucent, and FDA grade versions. Commercial grade silicone rubber is the standard of this type we offer. The others feature specific enhanced traits that make them ideal for their respective uses. The premium grade version differs from its commercial grade counterpart in the way it feature enhanced physical properties like elongation and tensile strength. Translucent silicone material is similar to commercial grade silicone, but is a translucent white in appearance. Its appearance is ideal for aesthetically sensitive applications. The FDA grade silicone elastomer is commonly used as seals in food handling applications because it is made with materials that conform to the standards set forth by the Food and Drug Administration (21 CFR 177.2600). Despite these different types of silicone sheets, they generally feature similar strengths.

CASIS mainly offers different grades of silicone material that feature unique characteristics. The difference between these “classes” of silicone lies in their specific application, texture, and appearance. Silicone rubber is used a great variety of projects, such as Solar modules, Glass processing, Woodworking, Food handling and construction. Such applications require specific qualities from their rubber. In photovoltaic Industry, CASIS can offer KS-EXR series, it was researched and developed by ourselves according to the specific using working condition and effective forms of solar laminate. In glass Industry, CASIS can offer three kind of grades of tensile strength of silicone vacuum bag for different application conditions. For woodworking industry, After several years of R&D, the upgraded new generation products are more polish, the configuration are more logical. We eliminated the unpractical products. At present, CASIS only has two kind of grades of tensile strength of silicone membrane with transparent and translucent color. For other related Industry, CASIS can provide a wide range of silicone sheets for different applications. Like hot press, card-making laminator and so on.