Silicone Rubber

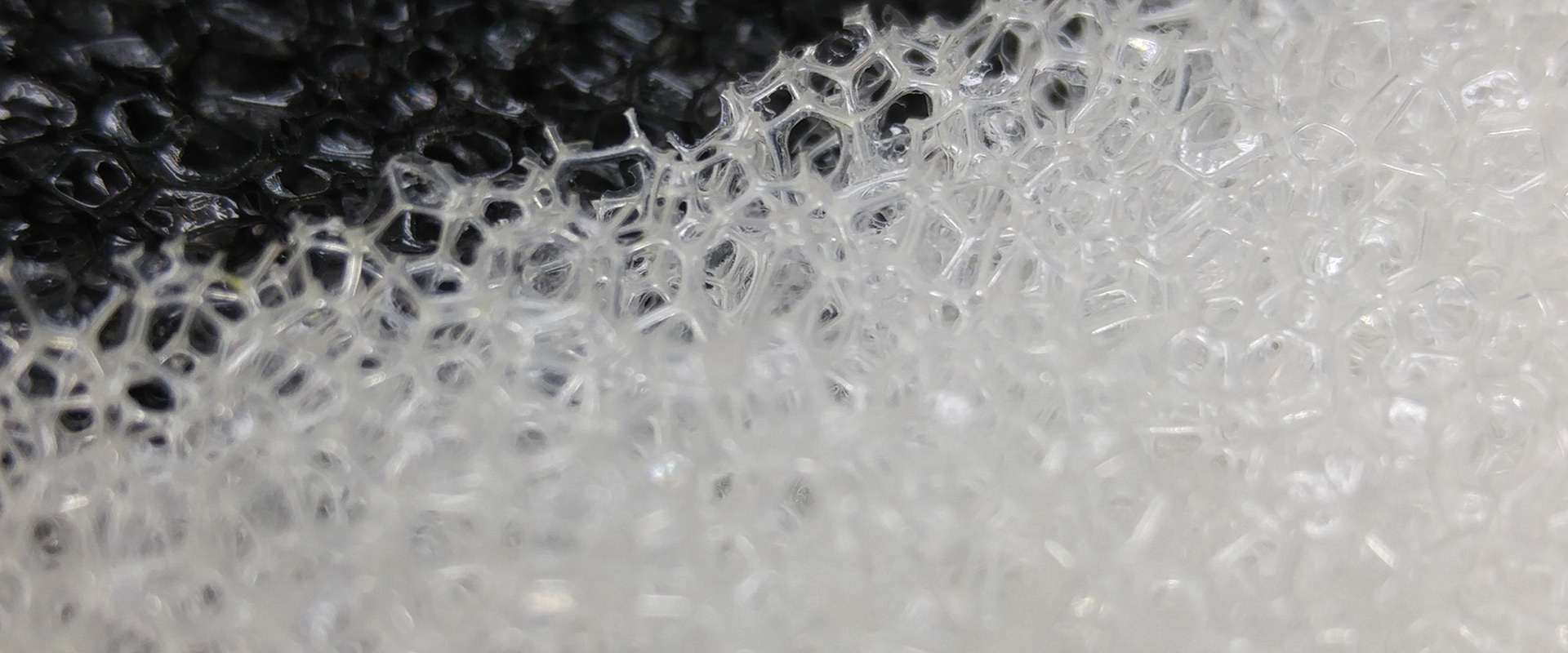

Silicone rubber was the result of the efforts of various chemical companies across the world searching for a material that could handle extreme temperatures. The first appearance of the silicone elastomer came in 1943. It was made available for mass consumption worldwide in 1947. In the decades since its debut, this silicone material has been popular for use in automotive, food handling, electronic, medical, and construction applications, among others. This is primarily because silicone rubber has a broad working temperature range that allows it to handle high and low extremes. Silicone products also exhibit good levels of weather and chemical resistance, making them ideal for a host of outdoor and industrial uses. CASIS offers a variety of different types of silicone sheets that are meant for specific purposes. The strengths of this synthetic silicone elastomer are hard to ignore.

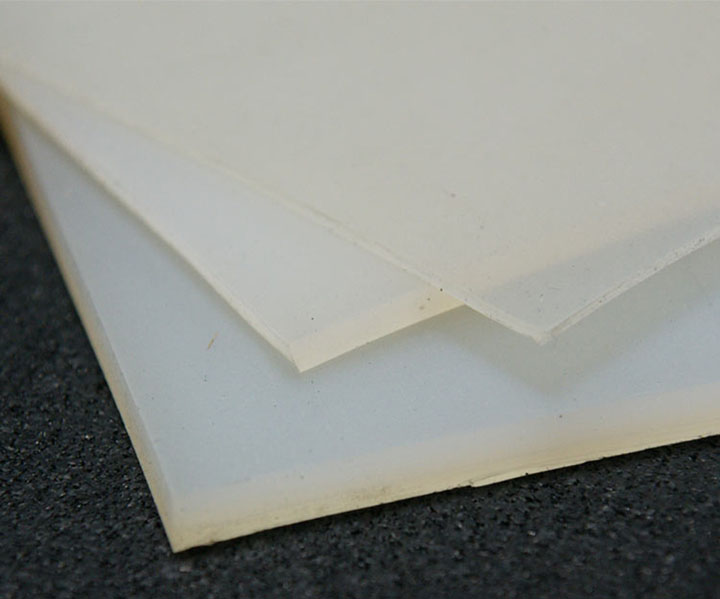

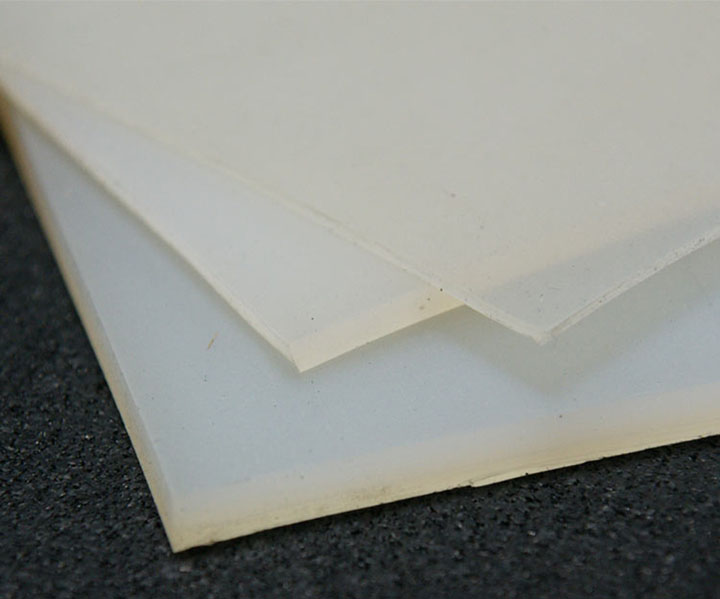

CASIS offers different grades of silicone material that feature unique characteristics. The difference between these “classes” of silicone lies in their specific application, texture, and appearance. Silicone rubber is used in a great variety of projects, such as food handling and construction. Such applications require specific qualities and capabilities from their rubber. CASIS offers silicone sheets in commercial grade, premium grade, translucent, and FDA grade versions. Commercial grade silicone rubber is the standard of this type we offer. The others feature specific enhanced traits that make them ideal for their respective uses. The premium grade version differs from its commercial grade counterpart in the way it features enhanced physical properties like elongation and tensile strength. Translucent silicone material is similar to commercial grade silicone rubber, but is a translucent white in appearance. Its appearance is ideal for aesthetically sensitive applications. The FDA grade silicone elastomer is commonly used as seals in food handling applications because it is made with materials that conform to the standards set forth by the Food and Drug Administration (21 CFR 177.2600). Despite these different types of silicone sheets, they generally feature some similar strengths.

A good range of temperature resistance is common to the various silicone grades. Silicone rubber was made to perform well in high and low temperature extremes. It is a generally stable material, with a temperature range going from -103° F to +500° F. This quality makes silicone products ideal for use in applications that see both very high and very low temperatures. It is popular for use as industrial gaskets in mechanical applications that produce high temperatures, such as combustion engines and electronic devices. Silicone rubber’s impressive temperature properties are further enhanced by its other weather and chemical related strengths.

Some applications may require exposure to ozone and UV rays. The silicone rubber used as seals and gaskets for construction equipment or in household items face the prospect of being in the outdoors. Outdoor use should not be a concern because a silicone elastomer can resist the harmful effects of outdoor elements like ozone and UV. Since it is an inorganic material, harmful organic matter such as fungi will not form on the surface of these sheets. Compared to sheets made of organic natural rubbers, silicone sheets last much longer when exposed to the environment.

Silicone rubber has another advantage over natural rubber: chemical resistance. Synthetic elastomers were originally designed to endure in the presence of chemicals, a direct response to natural rubber’s inability to do so. Ever since their arrival on the market, silicone products have been used in applications that see chemicals such as acetic acids, ammonia gas, sodium sulfate and more. It is important to note that the different silicone grades have slight variations on the specific types of chemicals they can resist, so it is always best to double-check with a customer care specialist, what type of silicone rubber is best for your application.

One of the unique features of silicone rubber is that it can be purchased in a wide range of different durometers. The durometer value is given to rubber to indicate the hardness and elasticity of different products. Silicone sheets are available in durometers of 40, 50, 60 and 70 A. The 40 A silicone rubber will have a higher degree of flexibility and pliability than the much harder 70 A version. Having the silicone products on offer in different formats like this allows the material to be used for a wide range of applications. Combined with its incredible ability to withstand extreme heat, both hot and cold, this means that silicone can be used in setting like gaskets, high-intensity laboratory equipment, low compression materials and much more.

Another way in which silicone rubber surpasses many other forms of rubber is the range of colors it comes in. The aesthetics of the silicone material might not be the top priority for a lot of people. But it can still be a key selling point and make the material appealing in a wider range of settings. Silicone sheets come in black, gray, white, blue, brown and red, offering a bold and striking look.

If you have a commercial, industrial, chemical, or outdoor application that needs the superior resistance traits of synthetic elastomers, look no further than silicone rubber. It will function in high and low temperature extremes while resisting the damaging effects of any chemicals and outdoor elements that may be present. CASIS also makes several different grades of silicone sheets available to consumers. We inventory a variety of gauges from 1/32” to 1/4” thick in styles and colors to match popular industrial needs. CASIS has the right silicone rubber sheets for you.