Silicone membrane for Veneer Pressing Machine

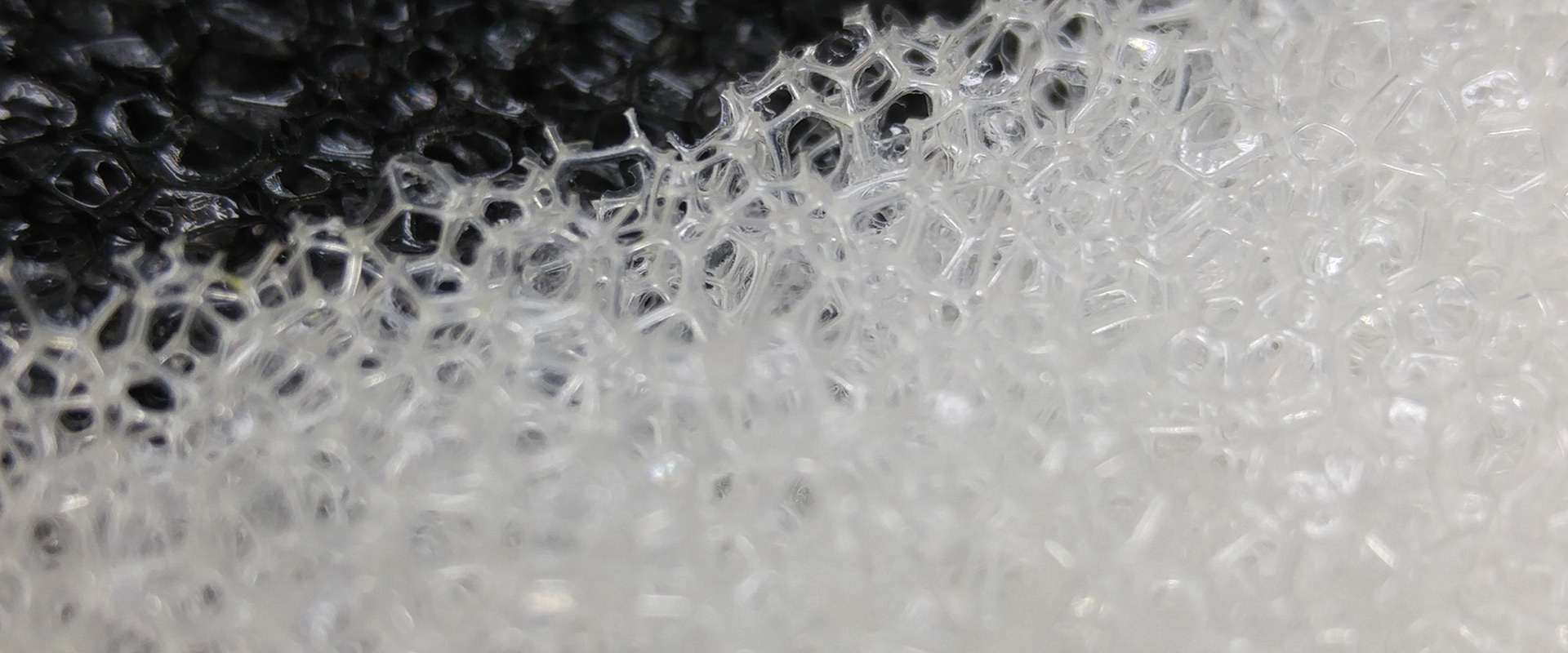

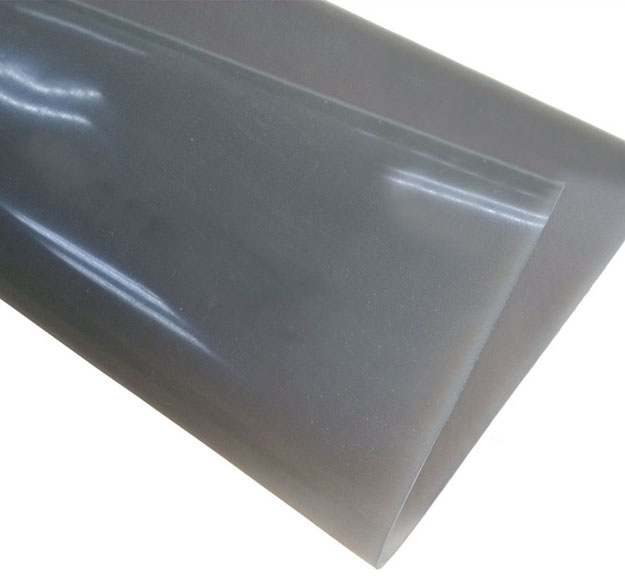

We have spent years formulating our own proprietary formulations to meet the demand put on today's silicone membranes used in the woodworking industry. This particular formulation is produced specifically for the wood manufacturing facilities throughout the world. With our state of the art manufacturing methods we are able to produce membranes without any seams up to 3.6 meters wide! These membranes feature high elongation, high tear strength, and low compression set. They are generally produced with a super fine fabric finish on both sides. This finish is highly sought after because of its ability to very quickly wick out all air during Vacuum procedures. Smooth finish is also available. These membranes have amazing reusability, durability, and also have extraordinary "Drawdown" strength and resiliency. This makes its performance remarkable when exposed to the high pressures and elevated temperatures they encounter.

Since the earliest days of 3D lamination, We have worked closely with 3DL component producers as well as membrane press and vacuum former manufacturers in order to supply the most effective, high-quality silicone membranes to the woodworking industry. We are honored to offer a consistent and valued product to the woodworking, solar, solid surface, composite, dye sublimation and steel-rule die industries.

Our silicone rubber membranes are valued world-wide for their consistency and durability. Silicone is available in four different durometers, as well as smooth or textured surfaces, ensuring that each customer can find the correct membrane for their 3D lamination application. Building on their success, CASIS continues to research and develop products specific to the various industries they serve.

Why 3D Lamination?

Amid growing concerns about sustainability and deforestation, 3D Lamination offers many of the aesthetically pleasing advantages of real wood without depleting that natural resource. And with the huge variety of 3D Laminates now available, shapes and surfaces that were once either very expensive or pure fantasy can become reality at affordable prices.

As a result, the demand for quality laminated materials has exploded, with companies around the world looking for quality membrane pressed components to complete their important projects.

Benefits of 3D Lamination

Flexibility in design

Cost Effective

Prevents Bacterial Growth and Contamination

Water Resistant

Create soft or rounded edges

Easy to Clean

Durable

Good for various commercial applications

Check out our wide range of products we have available and contact us today for consultation to determine which membrane material is best for your application. We pride ourselves on the ability to provide attentive customer service and timely results to help our clients get high quality materials they need for all woodworking projects.