CASIS specializes in providing commercial rubber sheets to consumers across the world. Our inventory of sheet rubber consists of various different types of elastomers. Each of these rubber products is meant for different types of uses. Some of them, like a natural gum rubber sheet, are great for use as general sealing materials. Others, such as a silicone sheet rubber rolls, are meant for specific applications involving very high or very low temperatures. Even aesthetic concerns are taken into consideration as we stock several different color rubber sheets. If you need a rubber sheet for your application, chances are good that we have the right sheet rubber available for you.

When you are driving back home today or walking around the city, take a look around. You might notice a construction site for that new mall or a street sweeper making its way down the bustling roads. These applications are common place for sheet rubber, but the average lay person may never be aware of it. Rubber sheet materialpermeates our everyday lives and its applications are broad and typically tied to the industrial world. However, some knowledge on these rolls of rubber can only help you realize how useful this product is in our everyday lives. Now let’s delve into the essentials of what is a rubber sheet and even take a look at how rubber sheet manufacturing is done.

To begin with, it is important to know that there are four broad groups that this product is typically derived from. These groups include: Recycled rubber, reclaimed rubber, synthetic rubber, and natural rubber. Recycled material is primarily made from recycled tire crumb that has been put back together using an adhesive. This is not to be confused with reclaimed material, which is also made from recycled tires and other discarded parts. Reclaimed rubber is de-vulcanized, which goes through vulcanization again to form a sheet rubber. Synthetic material is among the broadest category of rubber sheet material, but is mainly derived from butadiene and styrene, which are by-products of petroleum. These gases can be combined with several different materials to produce sheets that have different chemical and physical properties; creating a material that is ideal for many applications. Lastly, there is natural rubber material which is harvested from the Hevea Brasilinesis tree in areas of South America, Africa, and Asia. Through this process of extraction, sap or latex is taken out of the tree and left to heal in order to produce more rubber. These four different classes provide the basis of different rolls of rubber, and are used in various applications to accommodate the needs of our society.

Here at CASIS, we have a rubber sheet for almost any application. The various different types of sheeting rubber in our inventory include: EPDM Rubber, Neoprene Rubber, Nitrile Rubber, SBR Rubber and Silicone Rubber. Each type of sheet rubber is unique and well suited for different applications. Sheet rubber made from SBR and recycled rubbers function well as general-purpose seals and gaskets. They are fairly durable and easy to fabricate into various different types of parts. Natural gum rubber, in particular, benefits from a superior degree of flexibility. It even has a unique color: rubber sheets made from natural gum rubber come in a range from tan to brown. Natural gum and recycled rubber are not synthetic elastomers. They enjoy the benefit of being eco-friendly sheeting rubber products. Natural gum rubber is eco-friendly because it is made using naturally occurring materials, mainly the sap of the Hevea brasiliensis tree. There are no industrial or synthetic methods or compounds added to this sheet rubber. Recycled rubber, on the other hand, is eco-friendly thanks to the materials that make it. It is made using old rubber harvested mainly from vehicle tires. The method of making recycled rubber sheets actually takes non-biodegradable material out of the environment. This helps consumers by both helping to reduce waste in our ecosystem, as well as by coming at more affordable rates than their synthetic counterparts.

Sheet rubber rolls made of synthetic rubber may cost a little more, but they provide valuable physical and chemical properties that natural and recycled rubbers lack. EPDM, Neoprene, Nitrile, and Silicone sheet rubber should be used for the more industrial type of applications that see the presence of oils, chemicals, and temperatures of extreme degrees. Keep in mind that each particular type of synthetic rubber sheet has its own unique properties. For example, a sheet made of Neoprene may be moderately resistant to outdoor factors such as ozone, but EPDM resists ozone at far superior levels. Silicone sheet rubber may be able to comfortably handle temperatures up to 500° F, but Nitrile is a far superior rubber sheet for resisting different types of oils. Synthetic rubber materials are also available as different color rubber sheets, with red, gray, and white being the most common.

Fabricating rubber sheets is an important part of what we do. If you want a custom part fabricated from your sheet rubber rolls, we have several different fabrication options for you. We can custom fabricate products by hand, die, laser, or hydro-jet cutting methods. The type of method used can depend on factors such as budget, availability, and specifications. However, these methods allow us to meet the most critical of material tolerances and requirements. For the most accurate and high quality fabrication, we request that a drawing of the parts be sent to us.

COMMON INDUSTRIAL RUBBER SERIES

Industry is a very important part of the economy. In fact, it is a very important part of our modern lives in general! A vital part of any industrial application is the parts used in them. In this case, we are talking about industrial rubber products. CASIS inventories high quality rubber supplies that can be used in various industrial applications. We recognize that various industries have a vital need for crucial products made from rubber. Our line of quality engineered rubber products aims to satisfy that need. Industrial rubber can function as strong industrial seals, gaskets, pads, bumpers, shock absorbers, and more! Our inventory even consists of food grade rubber in case your application involves the use of consumables. Chances are that if your application needs a vital part made of rubber, CASIS can most likely provide it.

Among the most common types of industrial rubber products out there are seals and gaskets. These are present in the vast majority of industrial machines in factories and workshops across the country. Rubber industrial seals allow hard parts, such as metal, to make contact with each other without damaging the structural integrity of the machine itself. They are meant for protection. These engineered rubber products are a specialty of ours. We offer custom rubber gaskets made from a variety of different rubber sheets, from EPDM to Silicone. We welcome you to specify the exact requirements of your gasket and we will fabricate it for you via hand, die, and hydro-jet cutting.

Feet, pads, and bumpers are another very popular class of industrial rubber supplies. Also meant to act as protectors, they are meant to provide a barrier between equipment and the floors they are placed on. Depending on the particular application, you can choose from our array of natural and synthetic rubber padding. Rubber supplies make for the perfect pads and bumpers because they offer more elasticity, making sure that neither the machine nor the floors they rest on are damaged.

Of all the industrial-grade products made from rubber, perhaps none screams industrial strength more than our line of heavy-duty rubber sheets and mats. People use these tough and heavy industrial rubber products as a heavyweight version of pads and bumpers. These engineered rubber products are meant to take a beating. They are thicker and heavier than other types of rubber. Although they lack the amount of flexibility enjoyed by their standard weight counterparts, they make up for it with their excellent durability and abrasion resistance. After all, these rubber supplies are called "heavy-duty" for a reason.

Anyone who works in an industrial setting will be able to attest to the fact that some equipment is not always standing still. Many industrial machines are constantly in motion, moving and vibrating in one fixed position. This can be a danger to the overall safety of the machine and the workplace. We therefore make it a point to supply industrial rubber shock absorbers. Some of these shock absorbers are also heavy-duty, while others are more along the lines of standard matting. The secret behind their shock absorbing qualities is the rubber material that makes them. Products made from rubber benefit from a natural degree of shock absorption. Rubber tends to prevent any vibrations and impacts from reaching the surfaces below. Your machine will be protected while functioning on top of these tough industrial rubber products.

In case your industry involves food or any other consumables, we have you covered. We offer FDA-approved engineered rubber products made from silicone. These food-grade industrial seals are cleared for contact with consumable materials. The Food and Drug Administration (FDA), has strict guidelines for what rubber supplies qualify for use with food and drink. Our FDA-grade silicone meets their requirements. FDA silicone material can be used for any food packaging or transport application you may have.

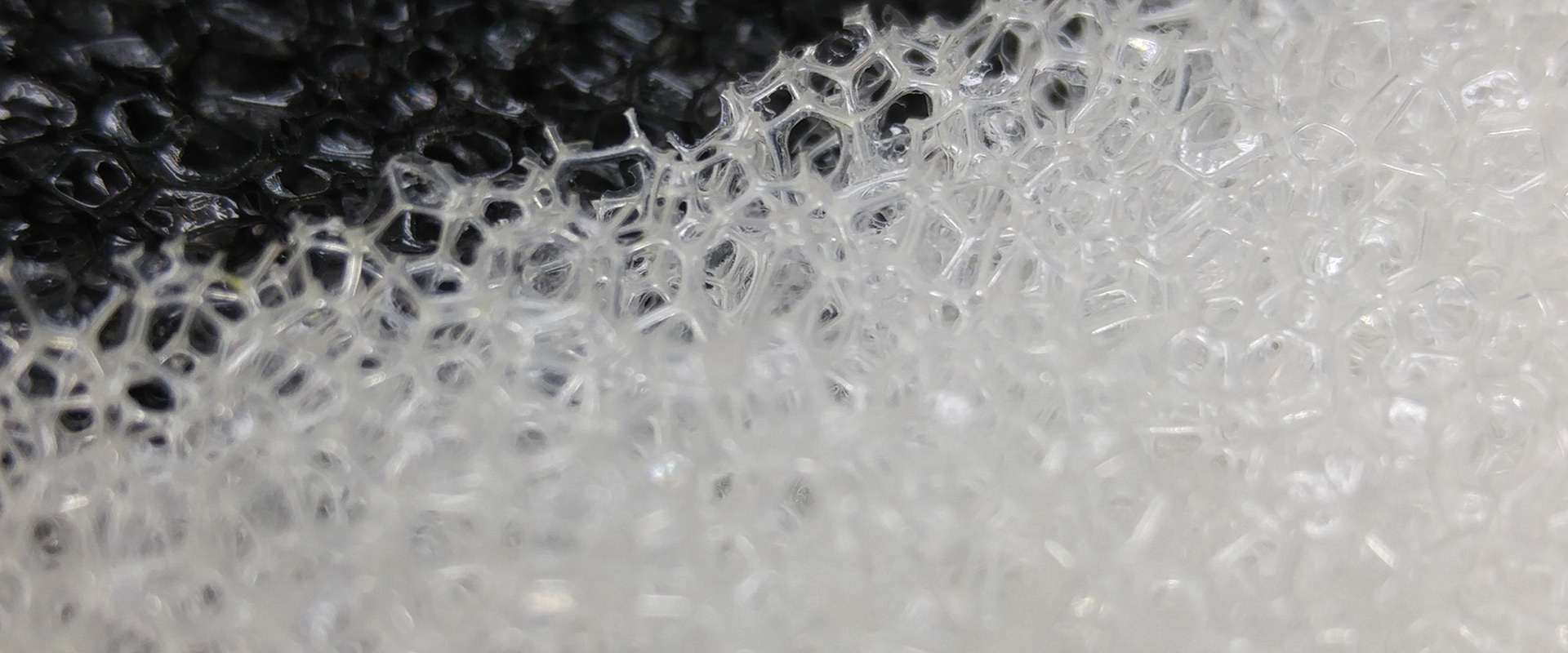

A unique type of industrial rubber that has seen increasing popularity in recent years is foam sponge rubber. Available in Nitrile, Neoprene, EPDM, or even blended variants, this rubber tends to be softer than its solid rubber counterparts. They are used in industrial applications that require softer rubber parts instead of the usual solid ones. While they generally fulfill the same uses as industrial seals and gaskets, the specific physical and chemical properties of the foam depends on what type of rubber it is made from.

Sheeting rubber products are most often sold in the form of rolls. Our sheet rubber rolls are usually stocked in gauges between 0.8mm to 50mm in thickness, depending on the specific type of elastomer. Since our sheet rubber is sold in roll form, they can be acquired in custom lengths of up to 7.5M,10M or 15M according to your specifications. This will help ensure that you have the exact amount of material you need for your project. More importantly, however, you should know which type of material to choose from. CASIS's line of industrial rubber products covers a wide array of possible industrial use. If you need dependable engineered rubber products that can function on an industrial scale, then you have come to the right place. From general gaskets to FDA-approved elastomers, our inventory is stocked for almost any industrial situation that may arise. Do not wait to get the right industrial rubber part for your application!