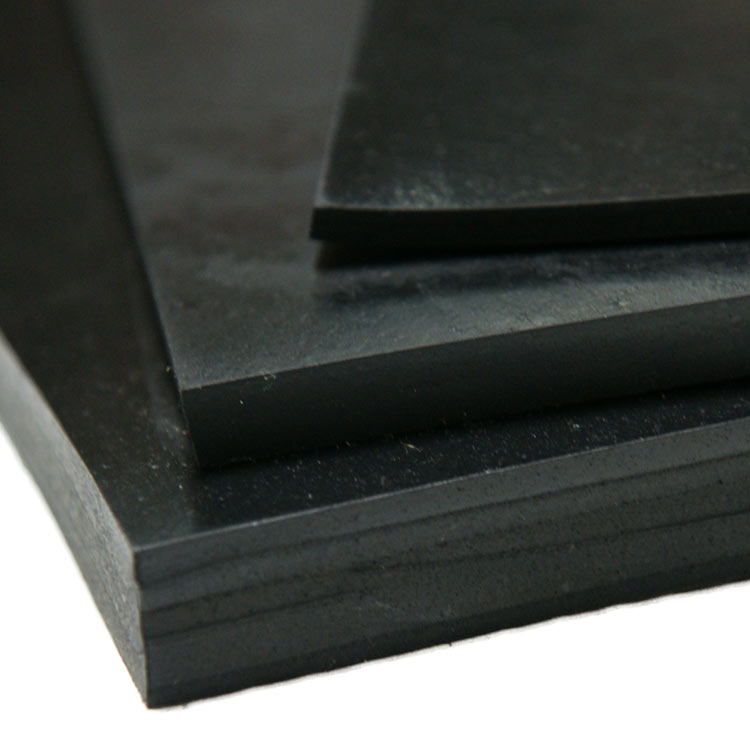

SBR RUBBER SHEET

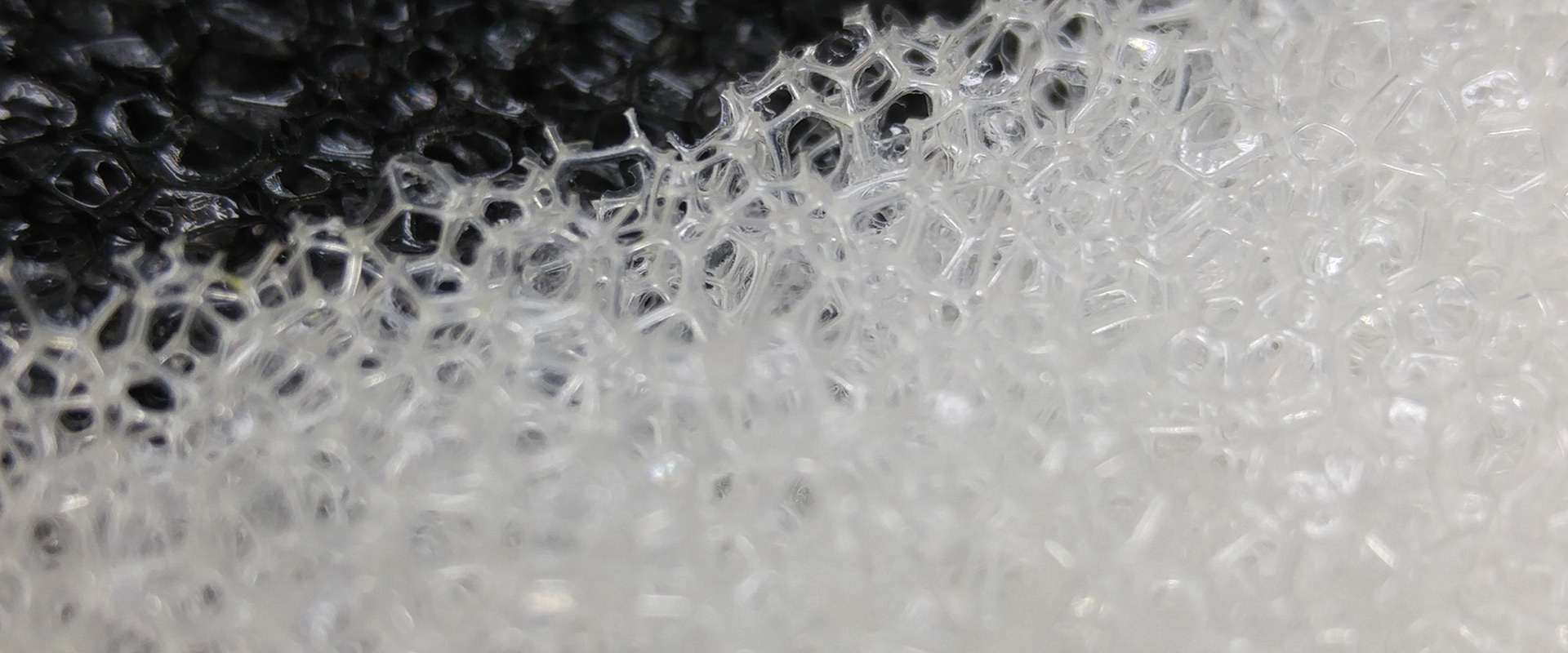

Styrene Butadiene Rubber, mostly known as SBR, is one of the best options when applied to general purposes. Compared to natural rubber, SBR shows better abrasion resistance and heat-aging properties. Though, the resilience and the physical properties tend to be lower than those of Natural Rubber. It is a copolymer of styrene and butadiene and has properties similar to Natural Rubber. It has good abrasion resistance, excellent impact strength, very good resilience and a high tensile strength. The temperature range of SBR is -40?F to 180?F. SBR can be compounded for use as lining rubber, conveyor belt covers and other extremely demanding applications. It can be compounded to provide very fine abrasion, wear, and tensile qualities. SBR can be readily substituted for natural rubber in many applications with significant cost savings. Resilience is about the same as natural rubber.

SBR Rubber is a copolymer of styrene and butadiene and has properties similar to natural rubber. Compared to natural rubber, SBR has superior processability, heat aging, and abrasion resistance but inferior elongation, hot tear strength, resilience and tensile strength. SBR has excellent mechanical properties, low compression set, and high resilience. It also has excellent dynamic and rebound properties and exhibits good resistance to acids, brake fluids, moisture, alkalis and salts. SBR may be substituted for natural rubber in certain applications, offering significant cost savings. Not recommended for use in proximity to oils and hydrocarbons. An economical red or black sheet can be used in low pressure applications with no oil resistance requirements.

• Characteristics:

Popular flange gasket material for hot or cold water, air and steam (not exceeding 100 PSI). All mating flanges wherever a quality rubber sheet is required. Remarks: Deforms to uneven flanges.

• Available in Full Rolls & Sheets

• Can be supplied in cut-to-width strips

• Operating Temperatures: -22° F to 158° F

FEATURES AND BENEFITS

• Operating Temperatures: -22° F to 158° F

Notes:

SBR offers little resistance to: Oils & Chemicals

SBR must be specially compounded to provide resistance to: Ozone, Sunlight & Heat