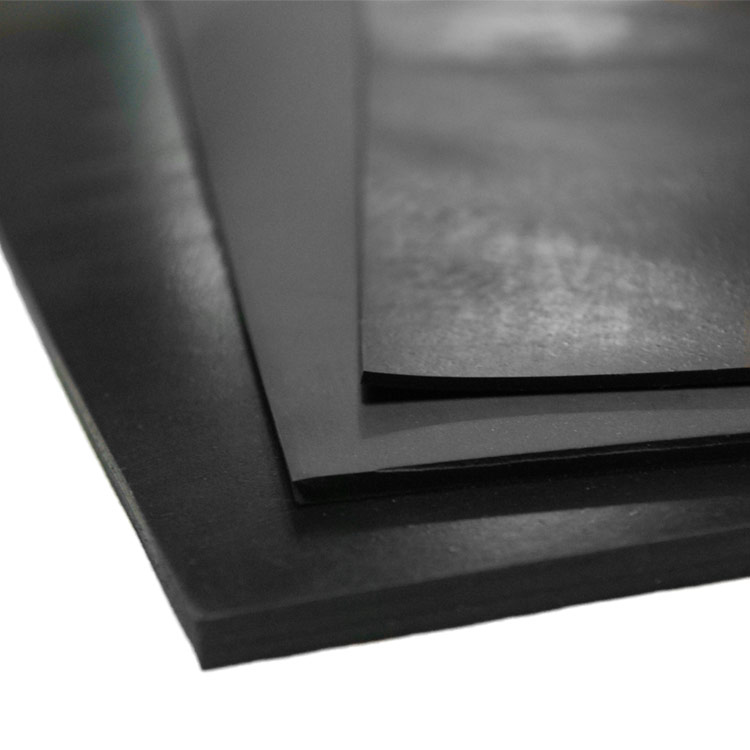

CR RUBBER SHEET

Neoprene rubber is a black colored rubber that is used in applications where moderate levels of oil, petroleum, ozone, and weathering-resistance are needed. Neoprene elastomers are very popular due to the broad range of applications in which they can be used. Variations in this elastomer exist in the forms of solid sheet, open cell and closed cell neoprene. Each type is suited for specific applications, but they retain mostly identical chemical resistance qualities. This synthetic elastomer was the answer to society’s need for an alternative to natural rubber that could fare better against chemicals and outdoor elements.

The first appearance of neoprene rubber was in 1923, but it was not originally the neoprene material that we know of today. Julius Arthur Nieuwland, a professor of organic chemistry at Notre Dame University, polymerized acetylene gas into a new synthetic compound that resembled rubber. This attracted the attention of the chemical company DuPont. They acquired the product rights from Nieuwland, but realized it was in a crude form that was not ready for mass production. DuPont then had to refine it in order to make it available for mass production. Their efforts paid off in 1931, with the creation of the neoprene rubber that we use today, which was originally named “DuPrene”. However, later in 1937, it was renamed neoprene and the rest is history.

The reason why the new neoprene elastomers attracted so much attention in the first place was due to the chemical resistance of neoprene. Around the time of its production, society was industrializing at a rapid pace. There was a need for a material that could resist the degrading effects of moderate temperatures, weathering and industrial chemicals. Natural rubber had been in short supply. When neoprene rubber came to the market, it instantly became a success.

Neoprene rubber is great to use for industrial applications. With a high temperature range of up to 220° F, neoprene material often goes into the production of industrial seals, hoses, and gaskets. Another capability of neoprene rubber that sets it apart from other materials is that it is fire resistant. This makes neoprene material extremely valuable for use in applications such as power transformers and other electrical applications, where safety is paramount in the event of a malfunction. Neoprene elastomers also behave in a perhaps unexpected way under extreme heats, becoming hard and brittle rather than melting – the reaction you might normally expect with rubber.

The material’s unique resistance to oils also makes it ideal for use in automotive applications. Neoprene rubber is very resistant to a variety of other petroleum-based solvents and acetic acids. The chemical resistance of neoprene is a key quality and makes this material extremely valuable. Having components made from neoprene material with these kinds of capabilities is important, especially in high-stress industrial settings with harsh conditions, because it can slow down the wear on individual parts and save you from wasting time and money on repairs. Neoprene elastomers help reduce the risk of such difficulties.

In solid form, CASIS offers hard neoprene and soft neoprene. They possess similar resistance properties but come with different degrees of durability. Hard neoprene rubber is a stiffer and denser version of regular neoprene. In its commercial version, neoprene rubber often contains a blend of other synthetic elastomers like styrene butadiene and nitrile rubbers. This makes for a more affordable sheet rubber. Hard neoprene elastomers are an excellent choice for applications that see a high degree of physical abrasions. It normally comes with a durometer range of 65-75, meaning that it can resist a higher degree of abuse than most other materials. A more elastic and flexible alternative is soft neoprene. Generally, it has a durometer of 40 and can be manipulated easily for more delicate projects. Despite these differences, all versions of neoprene rubber have enough oil and weathering resistance to make them desirable alternatives to natural rubber.

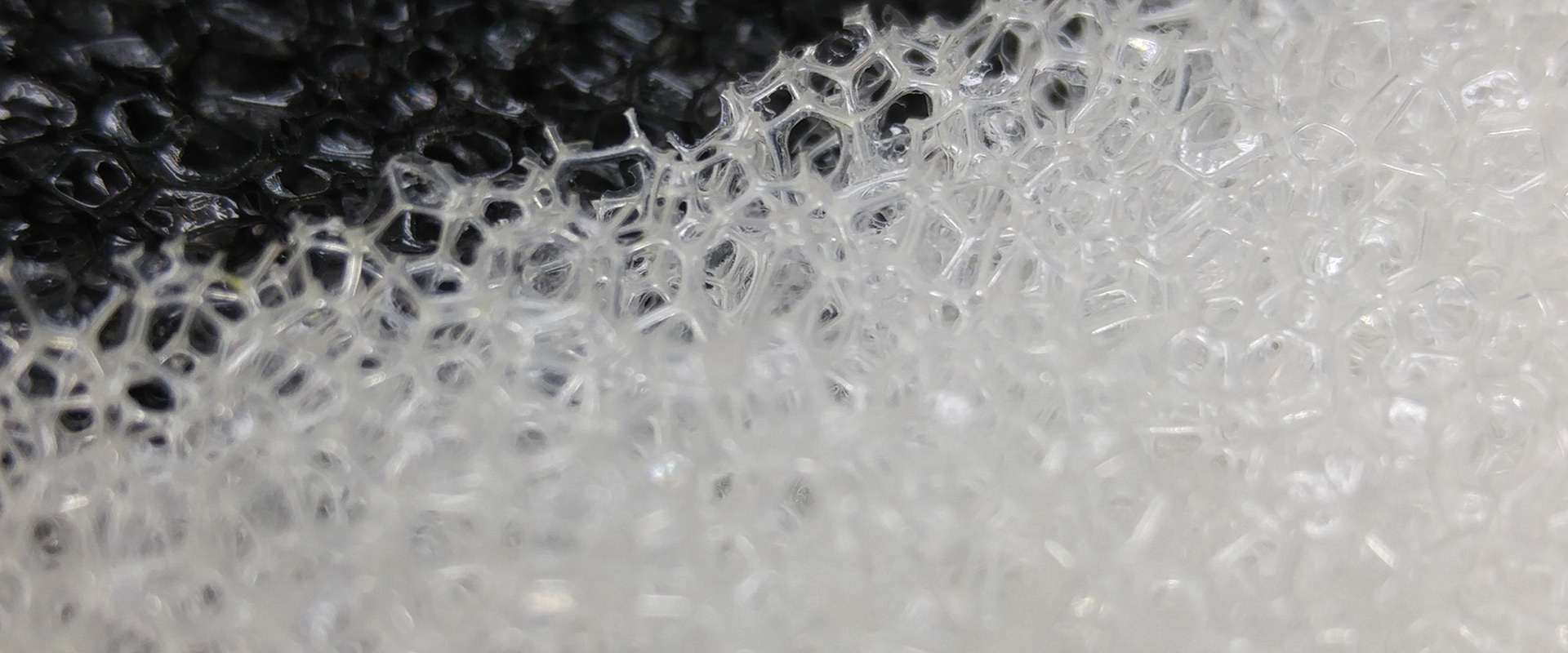

Neoprene rubber has been embraced for non-industrial commercial applications as well. For example, it is popular for marine applications due to its resistance to water. For such applications, neoprene material comes in open cell and closed cell variations. Closed cell neoprene is highly preferred as a wetsuit material because it is dense enough to both be waterproof and to insulate the body while being soft enough to be used comfortably on the human body. Its open cell counterpart is more porous and elastic. However, open cell neoprene fares better in terms of compression. It can return to its original form better than the closed cell version.

The characteristic oil and chemical resistance of neoprene has also been embraced by the food service industry. Restaurant kitchens see a lot of water, oils, and greases going around. Mats and other kinds of flooring protection products made of neoprene material are highly desirable for these kinds of applications because they can resist the degrading effects of oils and greases that could otherwise damage floors. This helps keep cooking areas safe, secure, and productive.

Whether you are looking to use solid, open or closed cell neoprene, all of these neoprene rubber variations have a low oxidation rate, making them effective in outdoor use. They can stand up well to the demands of UV rays and ozone, allowing neoprene material to provide a good level of resistance to weathering. This is similar to many of the qualities of neoprene elastomers. It isn’t the best at any one thing – other materials may provide more abrasion resistance or chemical tolerance. But the strength of neoprene rubber is the variety of features it provides, making it an excellent all-rounder.

Neoprene rubber is a very versatile material that can be used in a great number of fields where a rubber part may be needed. The chemical resistance of neoprene, as well as its other strengths, has ensured its popularity. Its use has expanded beyond the industrial and marine realms into more common areas. It can be used as a padding barrier in containers to allow for protection for sensitive objects. The use of neoprene has increased in the medical field in the form of orthopedic braces. Neoprene has even been used by the fashion world as an alternative to spandex.

Neoprene is among the most popular and widely used synthetic elastomers due to its all-around excellent qualities. Neoprene rubber is highly sought after to guard against high temperatures, liquids, chemicals, and UV rays. It can be found in different versions for different kinds of uses. One could use hard neoprene for heavy industrial projects, or they can use closed cell neoprene for making a wetsuit. Regardless of the application, the possibilities are great with this synthetic rubber.