EPDM RUBBER SHEET

EPDM rubber is a synthetic elastomer which is formally known as Ethylene Propylene Diene Monomer. EPDM products are offered in a few of variations. Their common feature though is that they are generally very good at resisting the degrading effects of weathering, ozone, and UV ray exposure. EPDM sheet rubber is highly recommended as a type of outdoor rubber for applications where there is significant environmental exposure.

EPDM rubber performs superbly in general exterior applications. Its chemical composition allows it to resist the cracking and discoloration that comes from exposure to UV rays and ozone. Cracking is particularly dangerous because it can affect the overall integrity and productivity of equipment or products. A good example of such an application for EPDM products would be in the form of window sealing strips in vehicles. These strips made from EPDM sheets are necessary for protecting the window glass and the vehicle, but they face a lot of exposure to the elements. However, since they are made of EPDM rubber, they will last for a long period of time without suffering from any degradation. But damage from ozone and UV rays are not the only challenges that this elastomer can fight.

Water is another potential hazard that is unable to dent EPDM. After all, it would not be a true outdoor rubber if it could not handle moisture. Normally excessive amounts of water can stain a material, cause it to warp and even cause mold or mildew to form. EPDM sheet rubber does not suffer from this problem and can endure even when exposed to heavy rainfall. EPDM sheets are often used in situations when a good degree of waterproofing is required. EPDM sheet rubber products also use a blend with SBR, another form of rubber that helps to add an even higher level of durability to the finished product.

In addition to being a great elastomer for outdoor use, EPDM products have a very good degree of chemical resistance. EPDM rubber is considered a non-oil resistant material, meaning that it does not hold up well in the face of oils like gasoline or kerosene. EPDM sheets do, however, make up for this in the way they handle a variety of other chemicals. It has good resistance to anti-freeze, synthetic detergents, acetone, boric acid, ethanol, formaldehyde, mercury, potassium sulfate, silver nitrate, saccharin, and even steam. It also has a great working temperature range. It is able to endure temperatures as low as -40° F and as high as 212° F, making it very well suited for a wide range of applications. These qualities have made EPDM rubber popular for use in industrial settings, such as in the form of seals and gaskets.

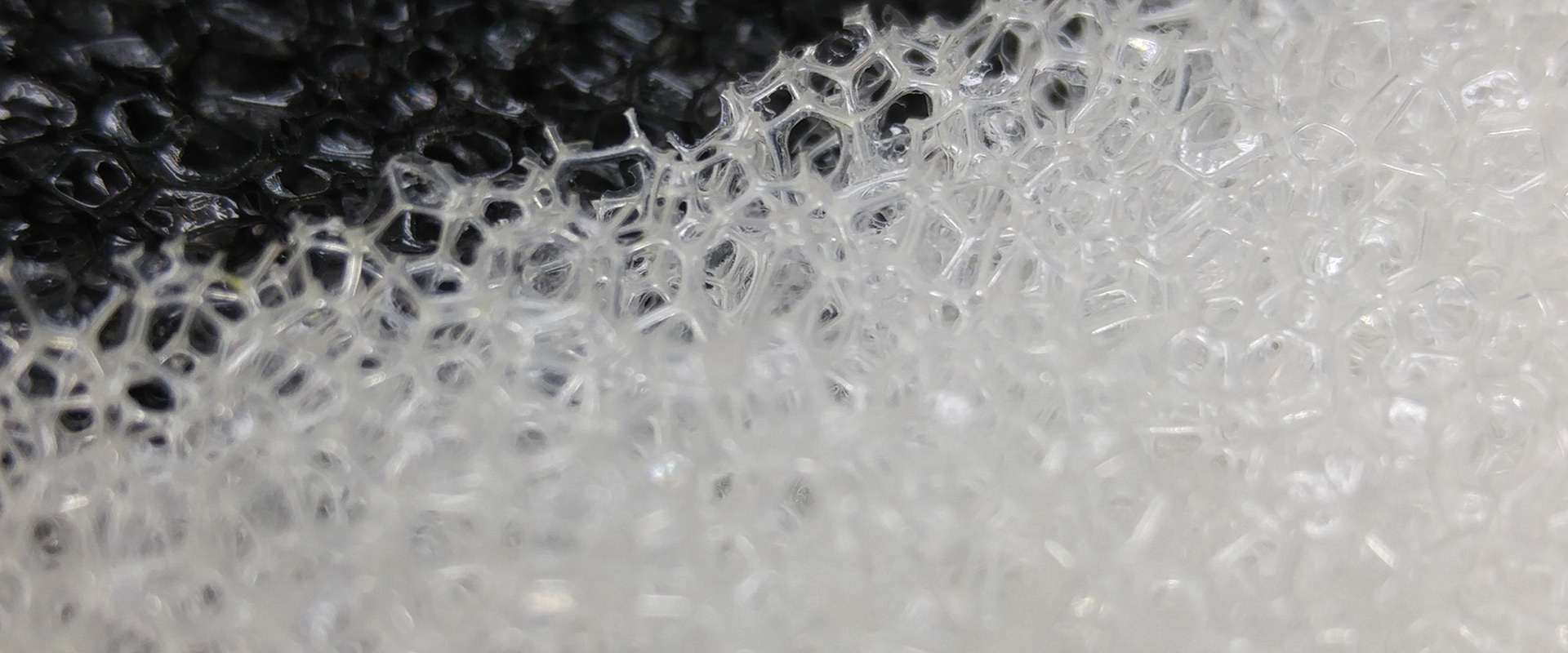

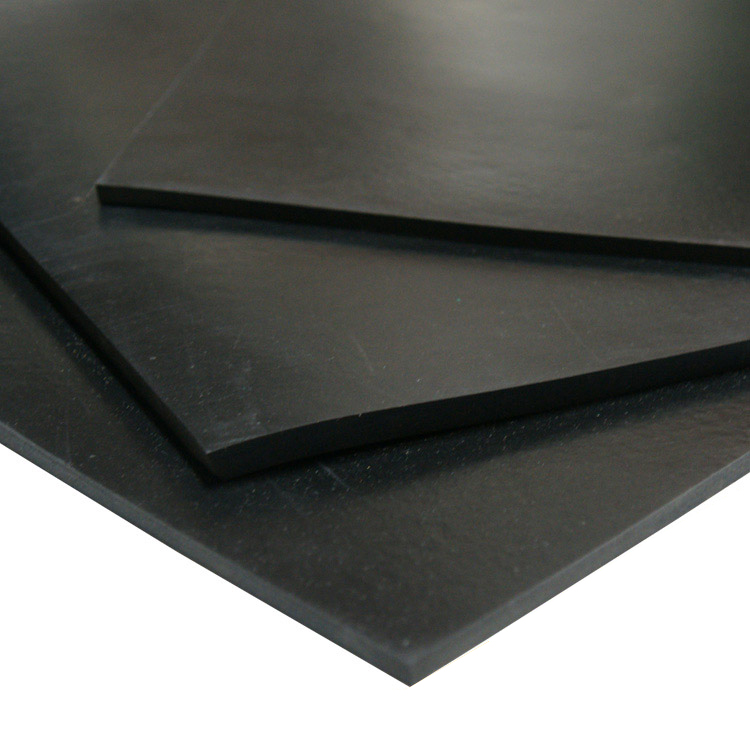

EPDM rubber is available in solid and cellular forms. The solid form of EPDM sheet rubber is generally denser and better suited to more physically demanding applications. It does not compress very well, which means that it will retain its original solid form in the presence of physical pressure. The cellular version of EPDM rubber is softer and can be compressed more easily for applications where flexibility is key. Apart from these differences, both solid and cellular EPDM material share nearly identical resistance attributes for outdoor conditions.

The hardness of rubber of measured through a durometer value and our solid EPDM rubber has a durometer of 60 A, which means that while EPDM material is fairly hard and dense, it does still have a reasonable degree of pliability and flexibility. It also has a minimum tensile strength of 725 PSI and an elongation of 300%. This feature means that EPDM products have a greater level of versatility and can be used in a wider range of applications. Another aspect of EPDM rubber which adds to its versatility is the range of gauges and sizes that it comes in. EPDM rubber sheets are available in a variety of thicknesses, the standard is 1-50mm in metric units and American units including special thickness 1/16”, 3/32”, 1/8”, 3/16”, 1/4”, 3/8” and 1/2”.

Given these qualities, EPDM rubber is a solid and dependable synthetic elastomer that is perfect in applications requiring effective outdoor rubber. With dynamic physical properties that make it ideal for use in a variety of situations, it thrives in outdoor and non-oil related usage. CASIS’ EPDM sheet rubber is a blend that contains styrene butadiene rubber, which is meant to give it a higher degree of durability and longevity. More importantly, industrial communities have embraced EPDM rubber because of its good chemical resistance and temperature endurance. If you have need of an outdoor rubber that has a proven track record of reliability against chemicals and inclement weather, then our EPDM material is the right elastomer for the job.