4MM Silicone Rubber Sheeting For Solar Module Laminator

4MM Silicone Rubber Sheeting For Solar Module Laminator

4MM Silicone Rubber Sheeting For Solar Module LaminatorAlthough also called diaphragms, sheets, or membranes, the solar panel industry tends to use the term membrane.

In direct response to the particular needs of the solar industry,

CASIS developed the 2nd Generation Silicone Diaphragm. Our grey, durometer 55 silicone also remains a popular option for many solar panel manufacturers. Specifically designed to resist the deterioration caused by EVA-outgassing, the Fifth Generation is used around the world by the leading producers of both thin-film and crystalline solar panels. Building on their success, WE continue to research and develop products specific to the various industries they serve.

Area of application - Solar PV Laminating Machine

Technical Data:

|

Type |

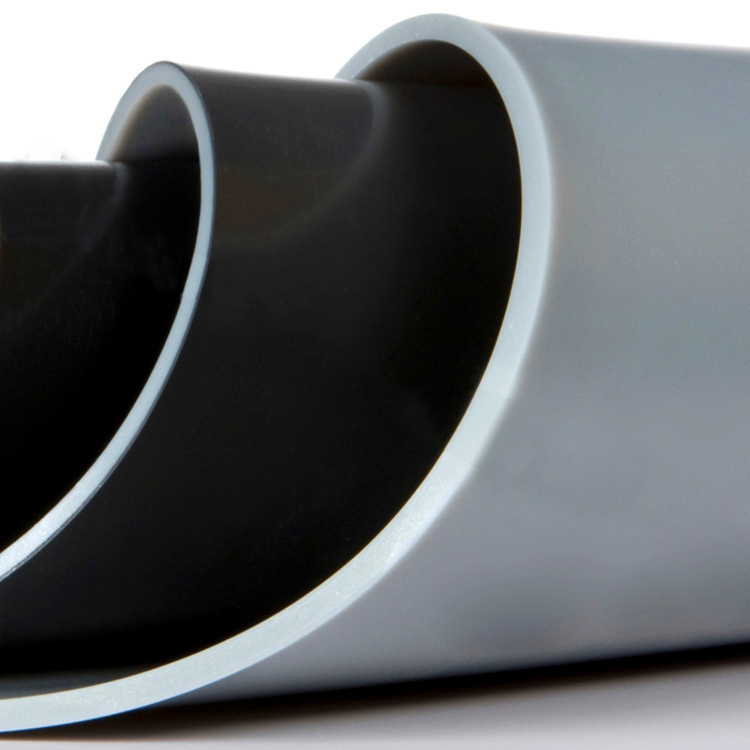

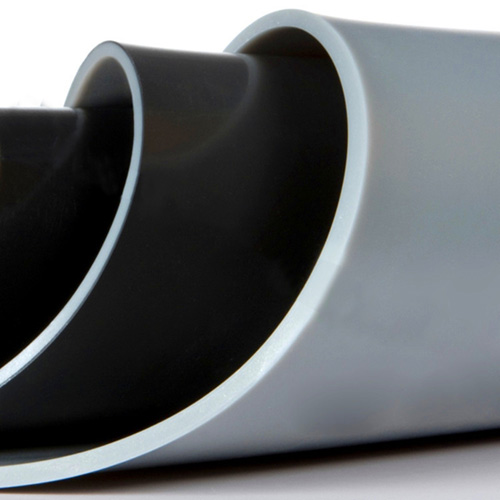

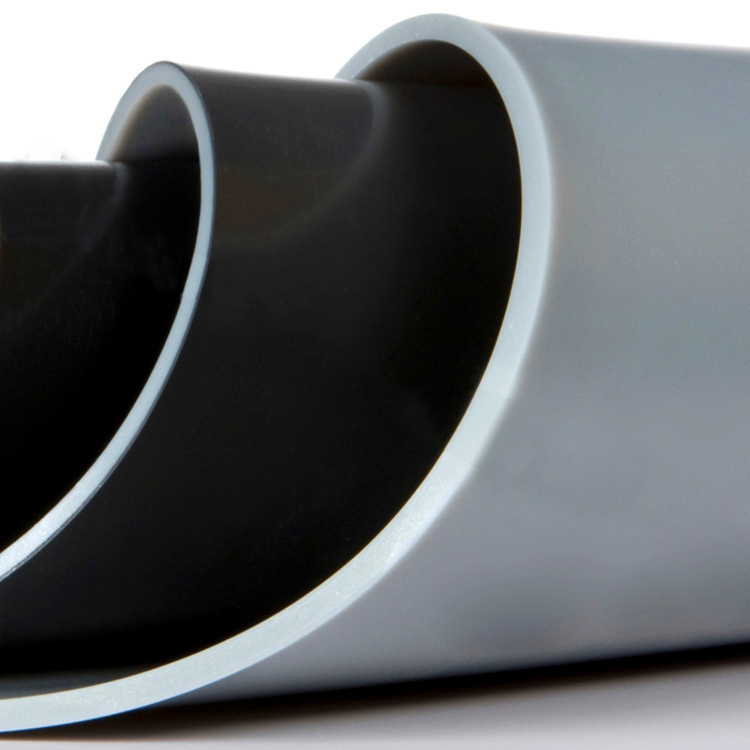

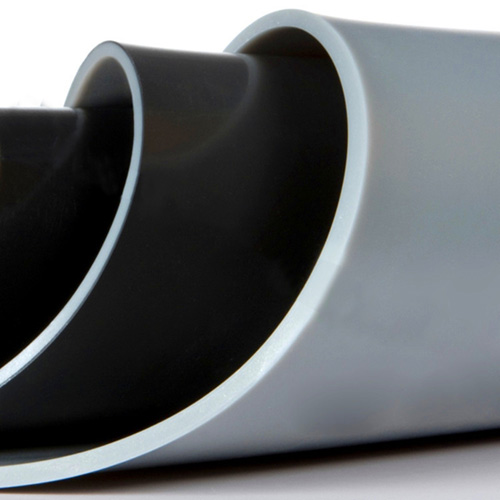

The Fifth Generation KS-EXR668 |

The Second Generation KS-EXR268 |

Material |

Backing material(buffering surface)

- Silicone - gray |

Silicone - gray |

Covering layer (eva resistant working surface)

- Special layer - Fluorine rubber - black |

|

Thickness, mm: |

4 |

4 |

|

Thickness tolerance, mm: |

±0.02 |

±0.02 |

|

Width, mm: |

Max up to 3800 seamless |

Max up to 3800 seamless |

|

Length, m: |

Custom |

Custom |

|

Density, g/cm3: |

1,95 ± 0,05 (working surface) |

1,25 ± 0,05 |

|

1,25 ± 0,05 (buffering surface) |

|

Working temperature, °C: |

-60 ~ +250 |

-60 ~ +250 |

|

Tensile strength, Mpa: |

10.2 |

12.5 |

|

Hardness, Shore A: |

76 ± 2 (working surface) |

70 ± 2 |

|

62 ± 2 (buffering surface) |

|

Elasticity: |

200% (working surface) |

750% |

|

750% (buffering surface) |

|

Tear strength, N/mm : |

45 |

48 |

|

Color: |

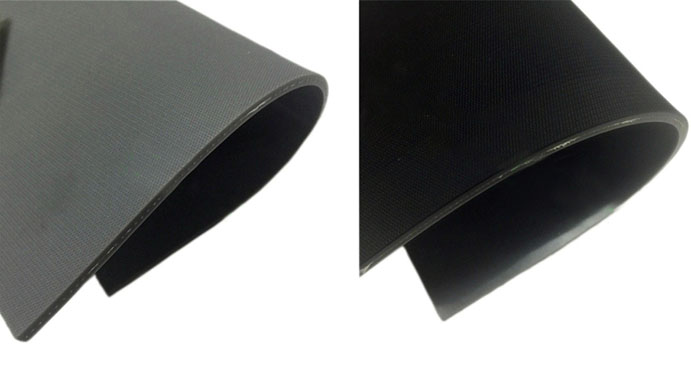

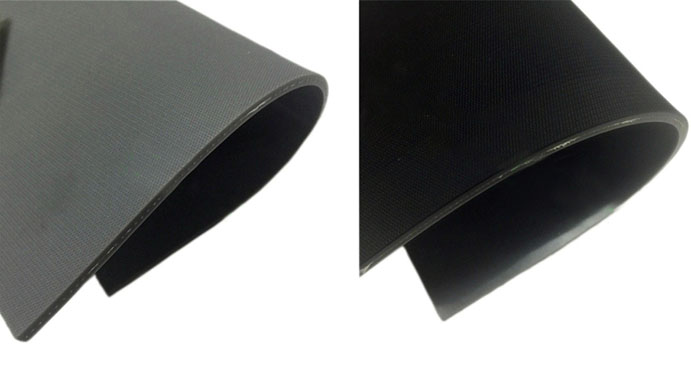

Gray/Black |

Gray/Gray |

|

Surface: |

Smooth/Textured |

Smooth/Smooth |

|

Feature: |

Aramid fabric inserted |

Aramid fabric inserted |

|

Resist to EVA: |

Excellent |

Good |

|

Normal Using Life: |

> 7000 cycles |

> 4000 cycles |

If you are intrerested in our products, please do not hesitate to conatct us.

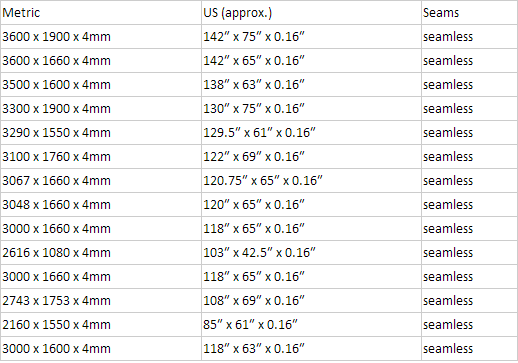

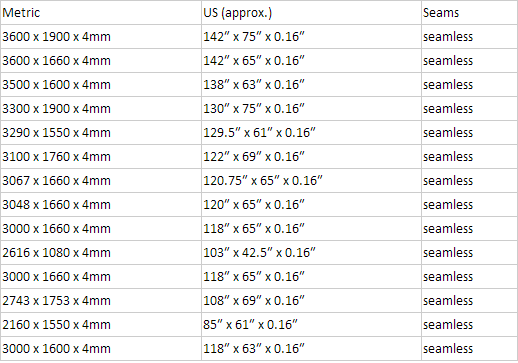

Dimensions Available as Follows:

Fabrication even beyond the standard size

Fabrication even beyond the standard size

Silicone Membranes FAQs

What’s the best membrane for our application?

This is a big question and really best discussed together on the phone. Determining factors would include your type of encapsulant, composition of the modules, size of the modules, and type of laminator.

How long should a diaphragm last?

This also depends on your encapsulant and type of module. Give us a call to talk about your product and processes to determine what you should be getting from your membrane.

What can we do to extend the life of our membrane?

Consider protecting it with a layer of PTFE sheet between the modules and the membrane. We have several options for this. And if you’re encapsulating with EVA, we should discuss the fifth generation KS-EXR668 Fluorosilicone membrane that is resistant to the outgassing from the EVA. The Fifth Generation KS-EXR668 option may give you far better life than your current membrane.