Silicone Vacuum Bag For EVA Laminated Glass Producing

Silicone Vacuum Bag For EVA Laminated Glass Producing

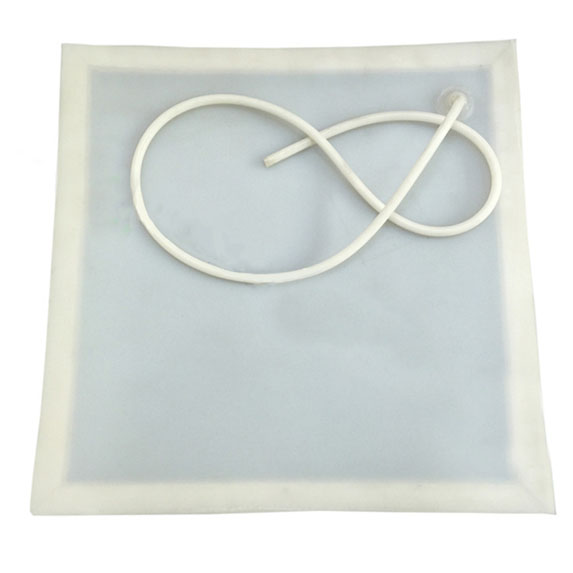

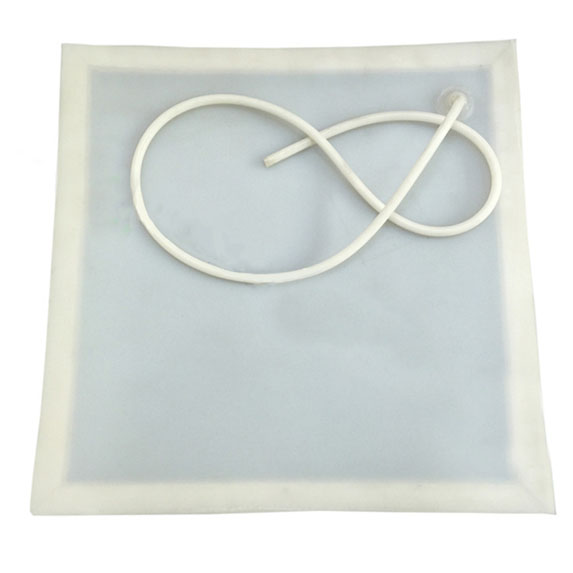

The combination of the silicone vacuum bags:

Upper Silicone Sheet

Down Silicone Sheet

Edge Gear (silicone sealing strips)

Silicone Tubes

Silicone Nozzles

PS: Before quoting, please let us know the size of your working area you are really requiring. “Outer dimensions and inner dimensions”

Product description and advantages

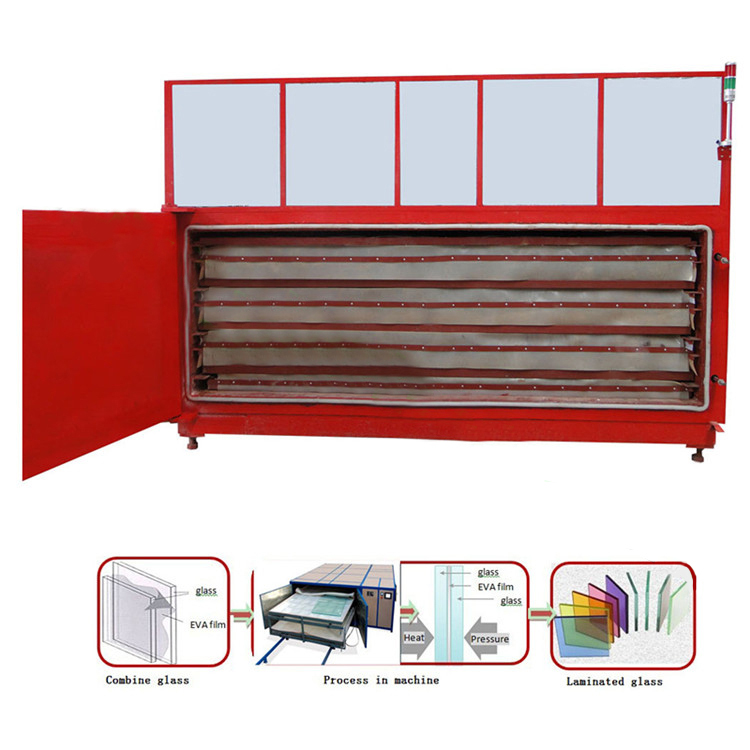

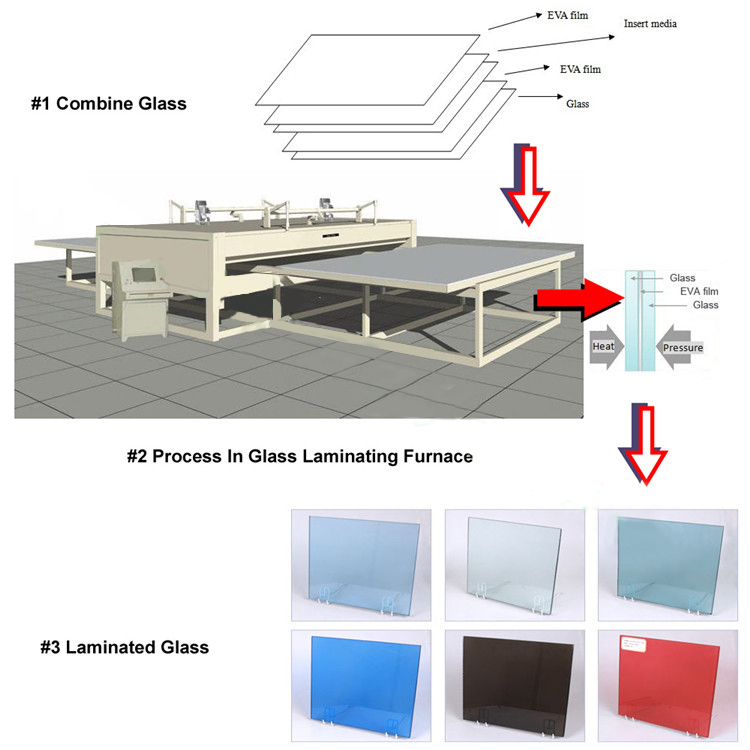

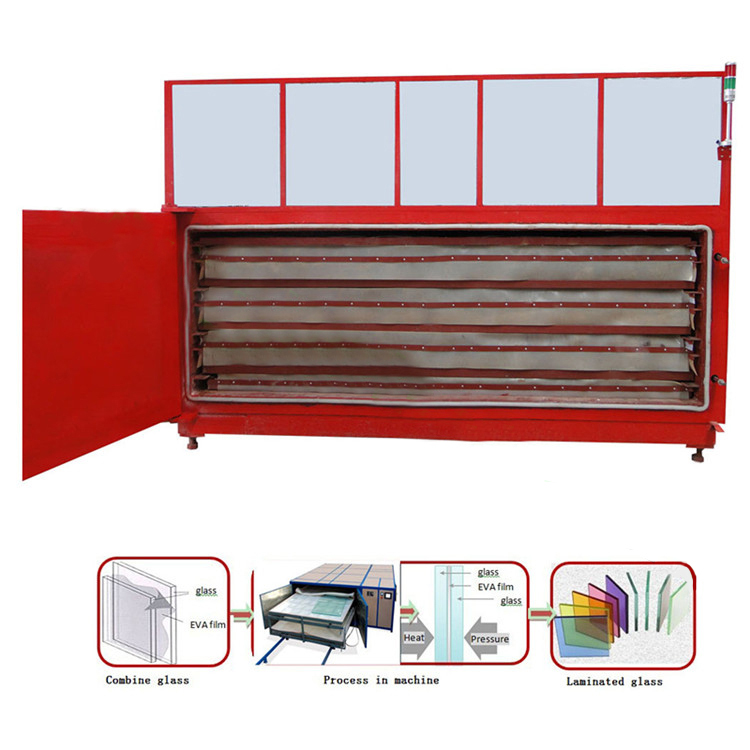

• Area of application: Glass Laminating Machinery

• Constant quality thanks to quality management

• Excellent elasticity

• Long-term flexibility

• High temperature resistance to 250°C

Standard dimensions

Width X Length: As requested

Material thickness: 2 mm 3mm 4mm

Technical Parameters of Silicone Vacuum Bag:

|

Model No. |

Tensile Strength

(MPa) |

Tear Strength

(N/mm) |

Hardness

(Shore A) |

Elongation

(%) |

Common Color |

Common Surface |

|

KS-EXS P116 |

6.5 |

26 |

55±5 |

450 |

Semi-Transparent/Blue/Red |

Textured/Smooth |

|

KS-EXS Z117 |

8 |

32 |

55±5 |

650 |

Semi-Transparent/Blue/Red |

Textured/Smooth |

|

KS-EXS G118 |

9.5 |

40 |

55±5 |

750 |

Transparent/Grey |

Smooth/Smooth |

Silicone vacuum bag is also called vacuum silicone bag. Made of silicone rubber material, it is highly essential in glass lamination, help to pump out the air between glass and EVA film, will fix the two glass on the right position to avoid the error. Besides, after fixing the glass, it is useful for the glue adhesion when the EVA film start to melt. It is high heat-resistance and tear-resistance. Each bag includes silicone sheet, buckle and nozzle, also the tube.

-

Durable & Flexible Silicon Blankets

This strong silicone pad meets the most severe industrial tests. It is made of special high temperature resistant silicon. The material will not become brittle after numerous heating and cooling cycles. It is resistant to high pressure forces when wrapping around glass during vacuum.

-

Patented Silicon Blankets Edge Seal

Top and bottom pad edges are specially designed, providing an airtight interlocking system. The higher the vacuum in between the top and bottom pads, the firmer the edges are sealed.

-

Please let us know your Max Glass Size, as we want your real working area

-

Features:

-

* It is high anti~tearing, able to bear high temperature.

-

* It's high flexible, inertia sufferance to avoid mucosity, bear oil & aging, its soft material is best suitable for hard glass, ensuring glass not bent and break in high temperature.

-

* Connecting vacuum pump, pump out the air and keep air pressure well in lamination.

-

* A whole set includes the nozzle, tube, silicone sheet, Sealing strips.

-

* At least 5 years’ service time.

-

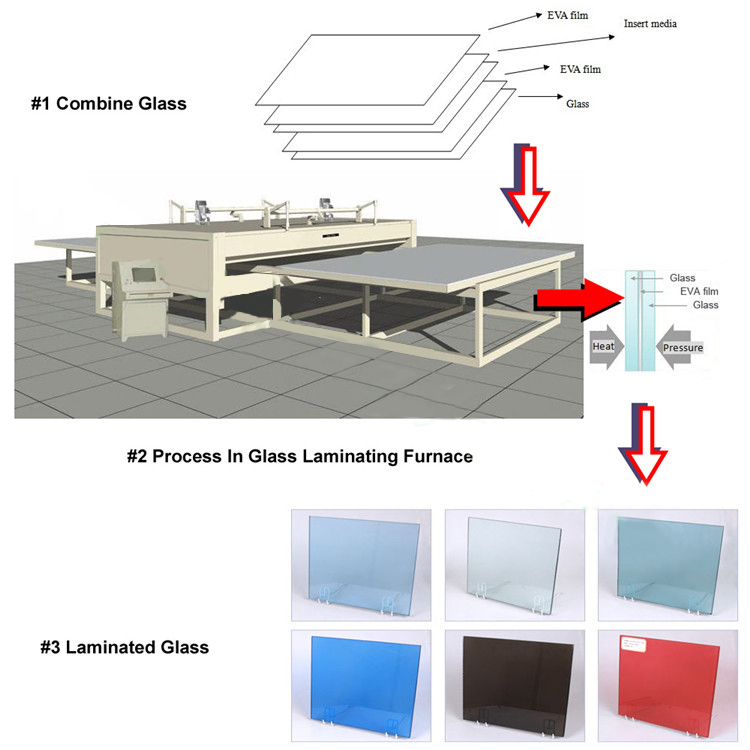

Processing Of Laminating Glass