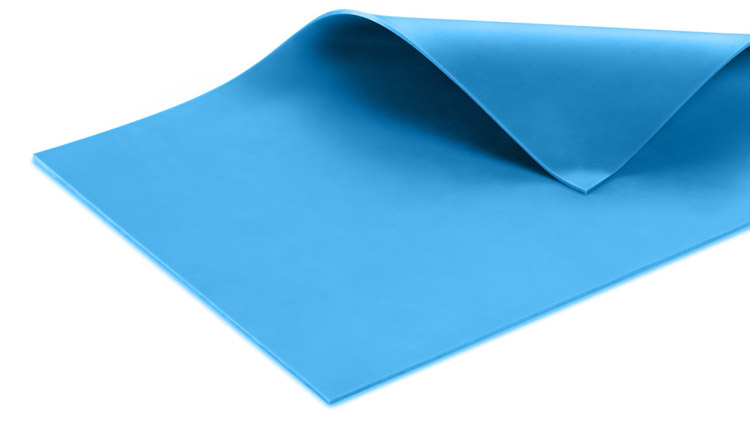

Blue Silicone Membrane Sheet For Vacuum Press Machine

Blue Silicone Membrane Sheet For Vacuum Press Machine

Since the earliest days of 3D lamination, CASIS have worked closely with 3DL component producers as well as membrane press and vacuum former manufacturers in order to supply the most effective, high-quality silicone membranes to the woodworking industry. We are honored to offer a consistent and valued product to the woodworking, solar, solid surface, composite, dye sublimation and steel-rule die industries.

Our silicone rubber membranes are valued world-wide for their consistency and durability. Silicone is available in four different durometers, as well as smooth or textured surfaces, ensuring that each customer can find the correct membrane for their 3D lamination application.

Building on their success, CASIS continues to research and develop products specific to the various industries they serve.

Standard Technical Data:

|

Model No. |

Tensile Strength

(MPa) |

Tear Strength

(N/mm) |

Hardness

(Shore A) |

Elongation

(%) |

Common Color |

Common Surface |

|

KS-EXD P66 |

6.5 |

26 |

65±5 |

450 |

White transparent |

Smooth/Smooth |

|

KS-EXD G86 |

9.0 |

32 |

60±5 |

650 |

Gray transparent |

Smooth/Smooth |

* KS-EXDG86 - high tear strength silicone rubber membrane for vacuum press

KS-EXDP66 - standard tear strength silicone rubber membrane

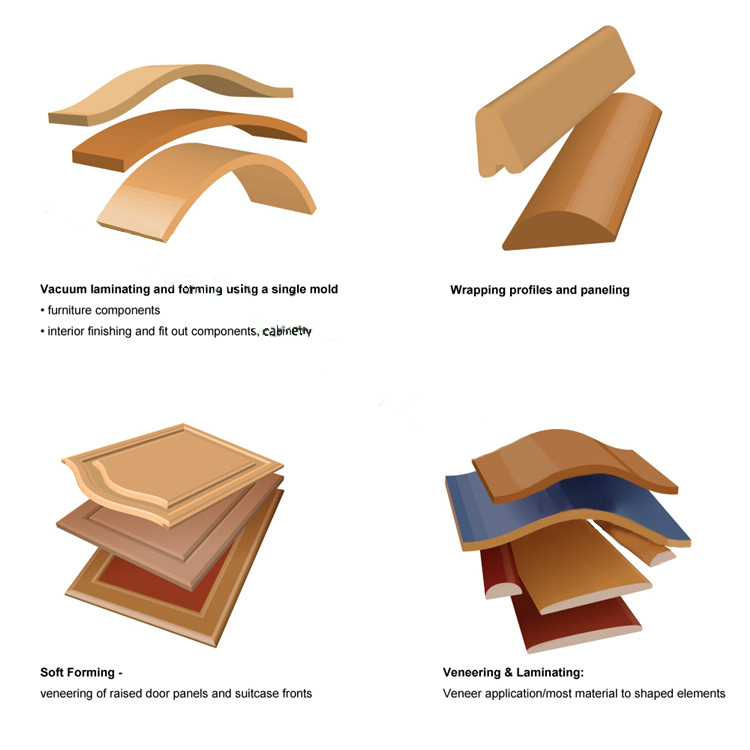

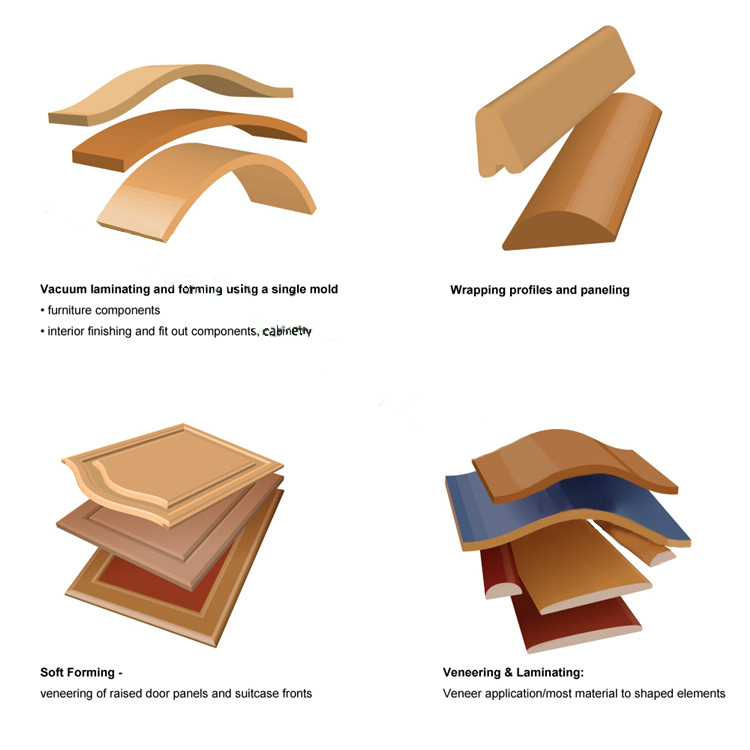

Area of application

Solar panel laminating, laminating of foil, veneer, production of triplex, thermoforming of solid surface and thermoplastic materials.

Why 3D Lamination?

Why 3D Lamination?

Amid growing concerns about sustainability and deforestation, 3D Lamination offers many of the aesthetically pleasing advantages of real wood without depleting that natural resource. And with the huge variety of 3D Laminates now available, shapes and surfaces that were once either very expensive or pure fantasy can become reality at affordable prices.

As a result, the demand for quality laminated materials has exploded, with companies around the world looking for quality membrane pressed components to complete their important projects.

Benefits of 3D Lamination

-

Flexibility in design

-

Cost Effective

-

Prevents Bacterial Growth and Contamination

-

Water Resistant

-

Create soft or rounded edges

-

Easy to Clean

-

Durable

-

Good for various commercial applications

Check out our wide range of products we have available and contact us today for consultation to determine which membrane material is best for your application. We pride ourselves on the ability to provide attentive customer service and timely results to help our clients get high quality materials they need for all woodworking projects.

Silicone Rubber Membranes FAQs

Do you have questions about our products or services?

Below are the most commonly asked questions from our customers? If you have additional inquires that are not addressed here, please contact us for more information.

What difference does the color make?

- The color is really just to make it easier to differentiate between different material durometers.

So why do you have some different colors for the same durometer?

- The answer to that is simply “Give the people what they want!” Some of our customers maintain that certain colors work better for them than another in the same mixture. Whenever we can, we’ll accommodate that.

What’s better, a smooth or a textured surface?

- It depends on what works best for your application. Some customers need a smooth surface for high-gloss finishes. Some prefer a textured or matte surface toward the heating platen for improved heat transfer. Some use the textured or matte surface down toward the foil to get a slightly different sheen on their foil, or to prevent darker foils from scuffing.

I call it a membrane, but my co-workers keep calling it a sheet and now you’re telling me some others call it a diaphragm! What’s the real name?

Although there are various names for the same product, we are able to decipher your needs and help you get the best product for your application, whether it’s a bladder, diaphragm or any other name your team calls it.