EPDM FOAM

Comprehensive introduction

EPDM is the acronym for ethylene propylene diene monomer rubber, and it’s is a type of synthetic rubber – specifically an elastomer which are versatile in a wide range of industrial and commercial applications. It outperforms in many aspects than other foam rubber material including aging properties, durability, compressibility, thermal durability and excellent slip resistance. This synthetic rubber is sometimes blended with other materials and is often used in areas requiring higher performance physical properties with respect to heat, ozone, and weather resistance. It is used in many applications in a number of industries such as construction, automobile, shipbuilding and the rail networks. Due to the superb air tight and water tight properties of EPDM foam it is generally used within the automotive, electronic and construction trades. It is also a very good material for jointing expansion, weather strips, glazing and closure seals as well as shock absorbers. EPDM foam washers, gaskets, seals, strip and sheet are also available in a high temperature variant taking upto 128°C as well as a semi open cell structure if needed.

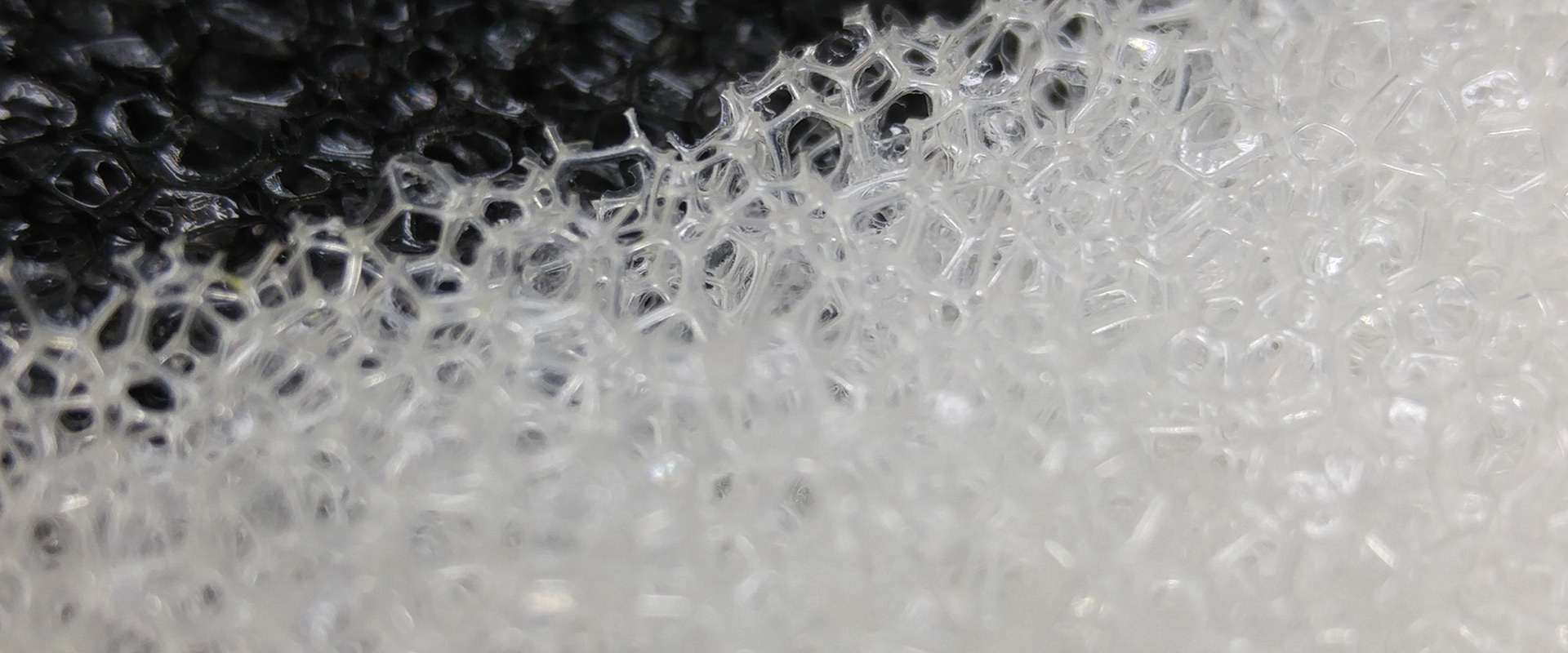

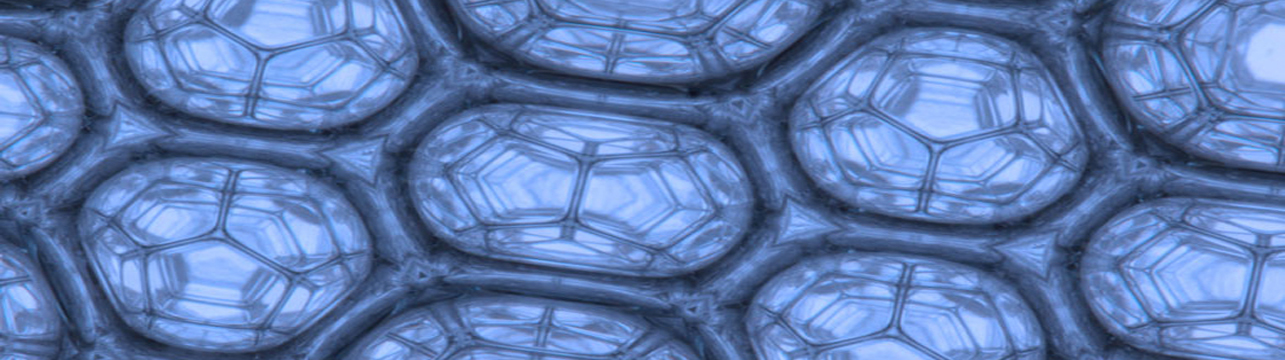

Foams are generated by forming gas bubbles in a liquid base which then begins to set over a short period of time, and the properties of the liquid and gas determines the final foam structure.

EPDM sponge rubber foams, in either closed cell OR semi-open cell form (open cell), have become more widely used in the automotive industry in an effort to meet worldwide material standards in new and existing applications. Casis’ proprietary EPDM foam technology has driven it to the forefront of becoming an excellent candidate for applications previously dominated by “cast PVC” foams or other semi-closed cell EPDM or PVN foams. Our EPDM foams are used for windshield seals, automotive shields that provide both moisture barrier properties and acoustic benefits, NVH functions, seals, gaskets, and a wide range of other unique applications. Certain EPDM foam products are being utilized in the appliance, HVAC, electrical and building industries.

The distinction between Closed Cell and Open Cell Foam.

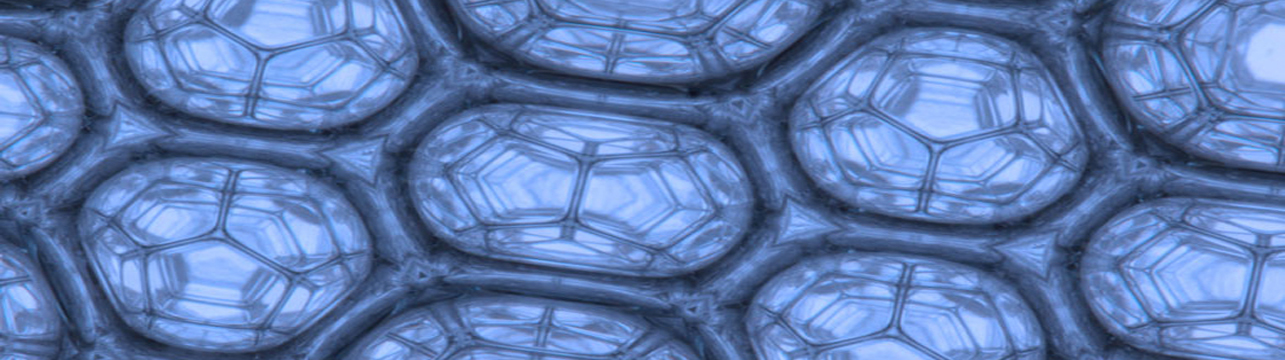

Closed cell foam – the bubbles are completely encompassed within the liquid and when it sets, the gases are entirely fixed within each individual bubble, creating a structure that is impervious.

Open cell foam – the bubbles burst during the foaming process to create and interconnection cellular network. This gives rise to softer and breathable foams.

Semi-Open Cell foam – this is created by physically bursting the closed cells to create a more open cell product which is softer and easier to compress.

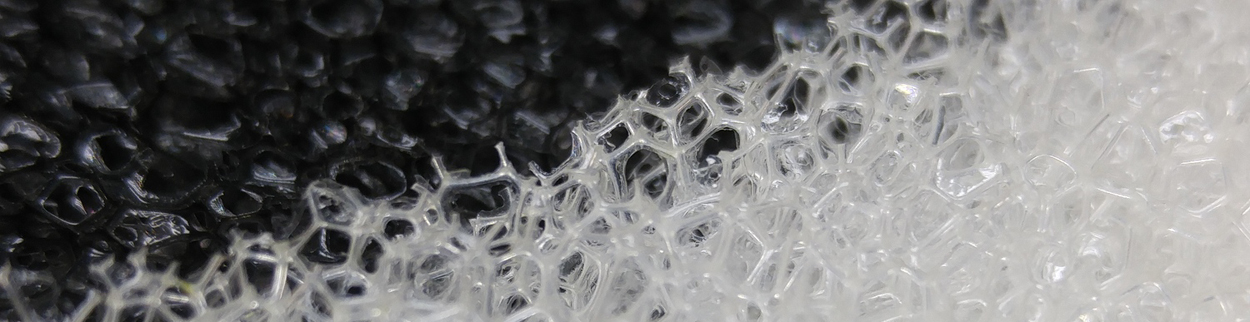

Open cell EPDM

Open cell EPDM

Open cell EPDM Sponge has been formulated to suit applications where sealing or cushioning is required for irregular depths or non-uniform areas. The material is very flexible and soft and has excellent properties for recovery without deformation when released after compression.

EPDM Open Cell Sponge Capabilities

It has similar performance characteristics to closed cell EPDM in terms of durability and resistance to UV, Ozone and external weathering. Open cell EPDM Sponge provides good temperature resistance in hot or cold environments. It also has good thermal properties in both extremes of temperature. Open cell EPDM materials do allow for ingress of air, dust, moisture until they are compressed by 80% of their thickness. Following this, the product becomes water and air tight and closed cell. Subsequently, they recover much better after compression when compared with closed cell EPDM. The open cell structure of this material provides flexibility and adaptability for excellent sealing capabilities which are comparable to closed cell EPDM Sponge when compressed to form an Air-tight seal. This unique material can be laminated with pressure sensitive to assist in securing placement during application to seal against water, dust, wind, noise and heat.

EPDM Open Cell Sponge/Semi-Closed EPDM Sponge Specifications / The main features of open cell EPDM Sponge are:

Open Cell Structure/Semi-Closed Cell structure

Super soft and conformable

Low Compression Load

Ozone Resistant

Good Weather Resistance

Fungus Free

Excellent ageing performance

Good water sealing

Good sound insulation

Open Cell EPDM Sponge provides good temperature resistance in hot or cold environments. It also has good thermal properties in both extremes of temperature.

EPDM Open Cell Sponge Applications

EPDM open cell Sponge is suitable for use in a wide range of applications in a variety of industries including Construction, Glass and Glazing, Shipbuilding, Railways, Aircraft and Aerospace, Electrical, Engineering and Automotive. EPDM open cell Sponge can be split to your required thickness and can be supplied as Foam Tapes, Foam Coils, Foam Seals, Foam Gaskets, Foam Sheets. Over the years CASIS has continuously adjusted and the products and technologies, no matter EPDM, NBR&PVC or other material.Our specialty and greatest advantage is EPDM open& semi-closure cell foam. The reason is our technology is closest to NITTO in the world. As we know NITTO is a great company for all sorts of applications. The market share of NITTO’s product is the largest in the world for EPDM open cell series product, whether it's automotive field, Electronic field or other related fields. For automotive field, Almost of all Japan Korea series car and other series car all designated NITTO's products as basic raw materials. NITTO absolutely is a leader in open & semi-closure cellular rubber field. They have always been our biggest and most powerful competitor and example. We always keep the modest & respectful attitude to be constantly learning, updating our own technology & formula. Meantime, we can do the corresponding adjustment for the cell state according to customers' requirement to meet different field's applications.

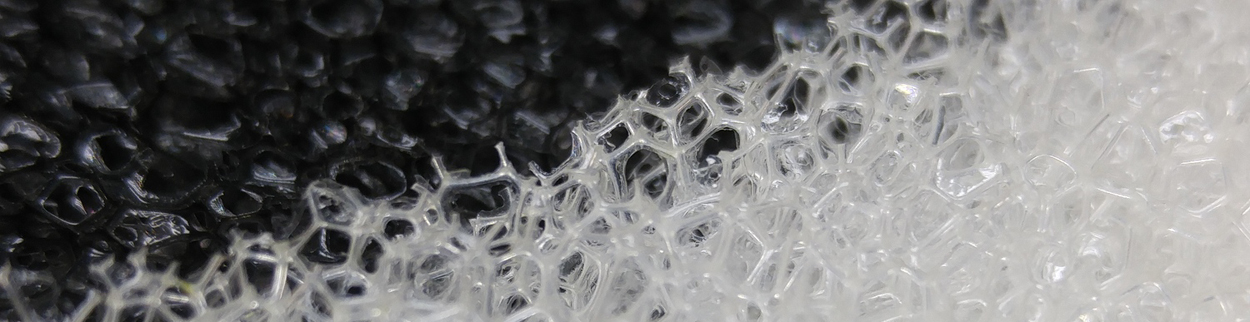

Semi open cell EPDM

Semi open cell EPDM

Semi Open Cell EPDM Foam combines the flexibility of open cell types with the excellent sealing capabilities of closed cell types (after compression). Combines the flexibility of open cell types with the excellent sealing capabilities of closed cell types (after compression)

Semi Open Cell EPDM is an extremely soft and flexible EPDM sponge rubber.

The cell structure of Semi Open Cell EPDM is created in the manufacturing process by physically “bursting” the closed cell structure in order to create a product that is softer and therefore easier to compress than the more traditional sponge rubber. This also means that Semi Open Cell EPDM offers much better recovery after compression.

The super-soft nature of Semi Open Cell EPDM provides excellent sealing capabilities once compressed. Due to low compression load the foam can compensate for dimensional deviations in substrates and can therefore be applied to both rough, smooth and low energy surfaces.

Semi Open Cell EPDM offers the following key features:

Resistance to ozone and UV light

High and low temperature resistance

Super-soft

Semi closed / semi open cell structure

Excellent acoustic performance

Good weather-ability

Low compression load

Good compression set

Good water and air sealing

Excellent ageing

Thicknesses available from 3mm to 50mm

Here at Advanced Seals & Gaskets we are able to convert Semi Open Cell EPDM into the following:

Sheets

Continuous rolls up to 1 metre wide

Seal tapes and strip from 6mm wide to 1 metre wide ( in any increment )

Die cut gaskets ( individually cut or kiss cut on rolls )

Die cut washers

Cut pads

Any of the above Semi Open Cell EPDM products can be supplied in either plain or self-adhesive backed.

Semi Open Cell EPDM has many different applications including:

Semi Open Cell EPDM has many different applications including:

Automotive application

HVAC units

Air duct sealing

Details :

a. NVH (noise, vibration, & harshness) seals, gaskets, pads, closure strips, pillar stuffers, cushioning in or around windshields, door panels, instrument panels, headliners, etc.

b. Acoustic / sound control in or around windshields, door panels, instrument panels, headliners, etc. These are often used alone or in composite to achieve STL (sound transmission loss) targets in a vehicle component “system”…i.e. a door “system” that includes the metal door, the glass, and the inner cabin door trim panel.

Note: In some systems, CASIS’s epdm foam with skin 2 sides might be used at 5mm (+/-) as a functional acoustic/moisture control material.

c. HVAC seals and gaskets providing air and water sealing.

d. APPLIANCES utilize these foams for the same performance reasons as listed above.

e. Applications that need very good UV resistance and a wide operating temperature are excellent applications for our EPDM foams: weather stripping; construction seals; window glazing seals, etc. These are used in custom profile form as well as die cut and stripping.

Over the years Casis has continuously adjusted and d the products and technologies, no matter EPDM, NBR&PVC or other material. Casis’ specialty and greatest advantage is EPDM open& semi-closure cell foam. The reason is that Casis’ technology is very close to NITTO in the world. As we know NITTO is a great company for all sorts of applications. The market share of NITTO’s product is the largest in the world for EPDM open cell series product, whether it's automotive field, Electronic field or other related fields. For automotive field, Almost of all Japanes series car and other series car all designated NITTO's products as basic raw materials. So NITTO absolutely is a leader in open & semi-closure cellular rubber field. They have always been our biggest and most powerful competitor and example. We always keep the modest & respectful attitude to be constantly learning, updating our own technology & formula. So we can do the corresponding adjustment for the cell state according to customers' requirement to meet different field's applications.

EPDM Closed Cell Sponge

EPDM is a flexible closed cell Sponge Rubber material designed to suit applications where resistance is required against UV light, Ozone and external weathering.

EPDM closed cell Sponge also has good temperature resistance in hot or cold environments. It also displays good thermal properties in both extremes of temperature.

Black EPDM closed cell foam has a good UV and ozone resistance and has good mechanical properties. Black EPDM foam is used for outdoor and indoor applications for example as shock absorption, sound reduction and insulation.

EPDM Closed Cell Sponge Capabilities

EPDM Closed Cell Sponge Capabilities

Different densities assist in applications to provide sealing properties to prevent ingress of Air, Dust, Moisture and Water.

As EPDM closed cell Sponge material is of a closed cell construction, it requires minimal compression to provide a seal.

The material is flexible and durable and has good recovery characteristics when released after compression.

EPDM closed cell Sponge has Flame Retardant qualities, specifications conform with and include FMVSS302 and UL94 HF1.

The material is Dust and Fibre free and can be used in any kind of public, commercial or industrial application without impacting on health or air quality.

EPDM Closed Cell Sponge Applications

EPDM closed cell Sponge is suitable for use in a wide range applications for a variety of industries including Construction, Glass and Glazing, Shipbuilding, Railways, Aircraft and Aerospace, Electrical, Engineering and Automotive. It is extensively used in Transport and Logistics applications for packaging and dedicated stillaging for product protection.

EPDM closed cell Sponge can be split to your required thickness and can be supplied as Foam Tapes, Foam Coils, Foam Seals, Foam Gaskets, Foam Sheets or Continuous Rolls.

Closed-cell foams are utilized in many of the same applications as our semi-closed foams. CASIS’s EPDM closed cell foam delivers excellent performance and durability for a variety of applications. Our proprietary “family” of EPDM foam products are used in the automotive industry as well as in appliance, weather stripping, and general industrial uses for a variety of applications and can be either die cut or in custom profile form, often with PSA.

NVH (noise, vibration, & harshness) seals, gaskets, pads, closure strips, pillar stuffers, cushioning in or around windshields, door panels, instrument panels, headliners, etc.

Acoustic / sound control in or around windshields, door panels, instrument panels, headliners, etc. These are used alone or in composite to achieve STL (sound transmission loss) targets in a vehicle component “system”…i.e. a door “system” that includes the metal door, the glass, and the inner cabin door trim panel.

NOTE: In some systems, CASIS’s EPDM foam with skin 2 sides might be used at 5mm (+/-) as a functional acoustic/moisture control material.

HVAC seals and gaskets providing air and water sealing

APPLIANCES utilize these foams for the same performance reasons as listed above

Applications that need very good UV resistance and a wide operating temperature are excellent applications for our EPDM foams: weather stripping; construction seals; window glazing seals, etc. These are used in custom profile form as well as die cut and stripping.

As for the market of close cell, we mainly focus on the development of high-density products. We reject all use of butyl compound for EPDM foam series, we always use 100% pure EPDM material to manufacture our products. The goal we need to chase is INTEREP in this area. As the world's top enterprise INTEREP Centre of excellence in the design and manufacture of closed cellular rubber, has been developing its activities throughout the world to provide high performance solutions for industry. So we can also provide different solutions for the fields of tight sealing, shock absorption and dampening, sound insulation, vibration; which enables them to offer a wide framework of products. Please remember that the values of our management is focused on the technical innovation.

General Characteristics for Close cell

General Characteristics for Close cell

Closed cell structure making it impermeable to air and water and therefore an ideal material for sealing against air and/or water.

Outstanding aging properties and will not go brittle over time.

Very durable and relatively cheap.

Available in a wide range – high temperature, hard, soft, supersoft.

Good UV resistance.

Good mechanical properties.

Wide temperature range.

We also supply EPDM foam rubber strips to many organisations as well as private individuals. Self-adhesive backing can be added to any EPDM foam strip. EPDM foam strips provide excellent seals in a whole host of applications. RH Nuttall Limited frequently supply a range of plain or self-adhesive backed expanded EPDM foam strip to solve issues such as air flow control, cushioning, water leakage and anti-vibration problems. Furthermore, due to the fantastic aging properties of closed cell EPDM foam it means that the sealing strip functions will not fail over prolonged exposure on a specific application. EPDM foam is available in various thicknesses ranging from 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm and right up to 40mm in thickness. But the most common is 3mm, 5mm, 8mm, 10mm, 25mm.

Foams typically fall into one of two categories. Open Cell, and Closed Cell. There is also a mixture of the two which is often called a semi open cell foam. Foam structures consist of a flexible material that is filled with voids, or bubbles. Two of the primary categories of foam are open cell foam and closed cell foam.

Our EPDM foam offerings include open cell, semi-closed cell and flame retarded foams; closed cell foam, and custom foam blended products. For more information on Casis’ EPDM foams, please view the pages in our drop-down menu. We are happy to answer any questions you may have, or discuss the specifications for your application.

Contact sales team by email at sales@casisrubber.com