NBR Foam Sheet: Best Insulation & Sealing Foam Material

NBR foam sheet material, also called Vinyl Nitrile foam or PVC NBR foam, is one of most useful and excellent foam materials. They can be fabricated to be Nitrile foam tapes, strips, gaskets, pads, sheets and so on. NBR foam are mostly used for seals, gaskets, heat insulation, soundproof and vibration dampening applications. They are foamed polymer blend of PVC and Nitrile rubber materials. It is foamed Nitrile foam not like the solid and rigid Nitrile rubber. They are used in applications where loss of energy is high. They greatly contribute to heat insulation owing to their closed cell structure and they are perfect insulation materials you can confidently use for air-conditioning and refrigerating installations owing to their high resistance against vapour diffusion. They are resistant against sunrays. They are highly elastic and long-lived materials. They are used in areas where the ambient temperature continuously and rapidly varies without any problem. They are produced not only as sheets but also as pipes to be used particularly in pipe installation insulations. They are coated with various foils to increase their insulating values and to provide protection against external factors.

Here is how you can easily distinguish NBR foam from other foam materials:

When you get a piece of NBR foam sheet from foam suppliers, you can quite easily distinguish it from other foam materials like EVA foam, Polyethylene foam and Neoprene sponge by following the below 3 main methods:

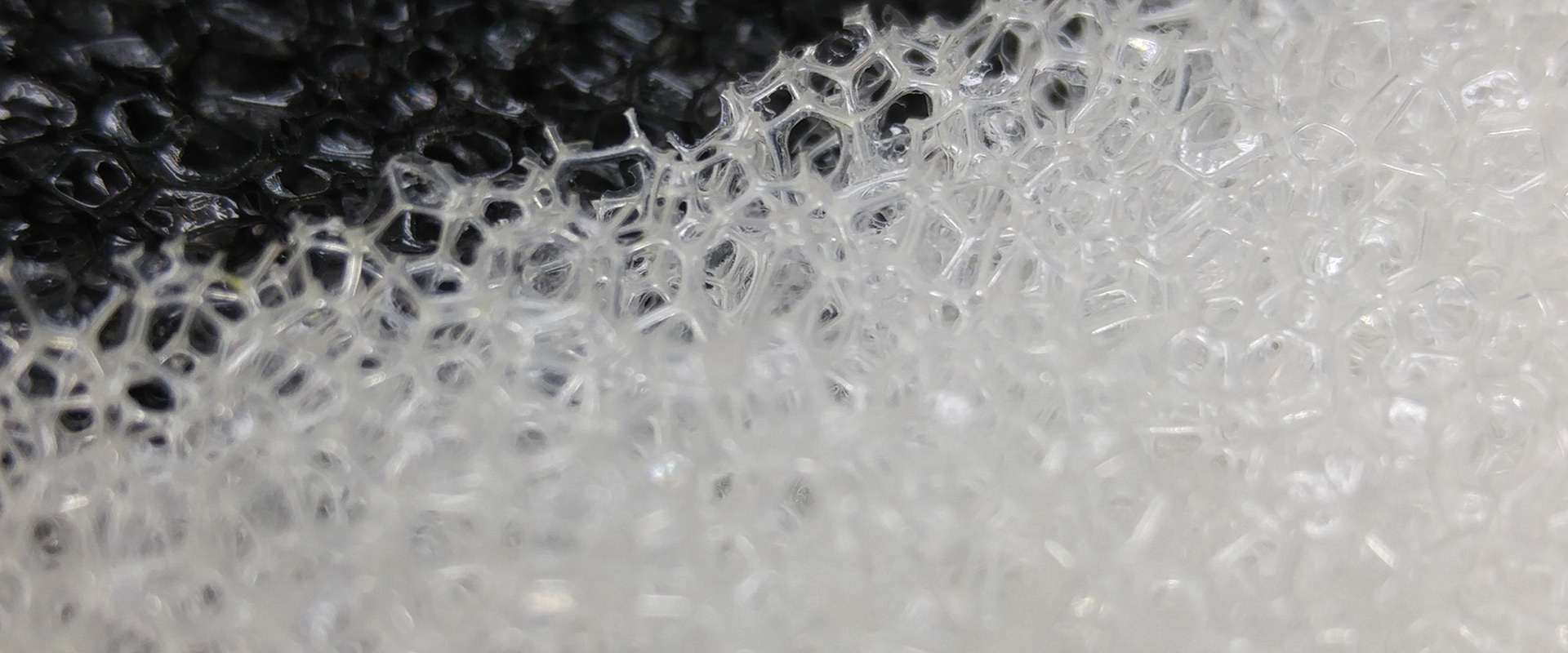

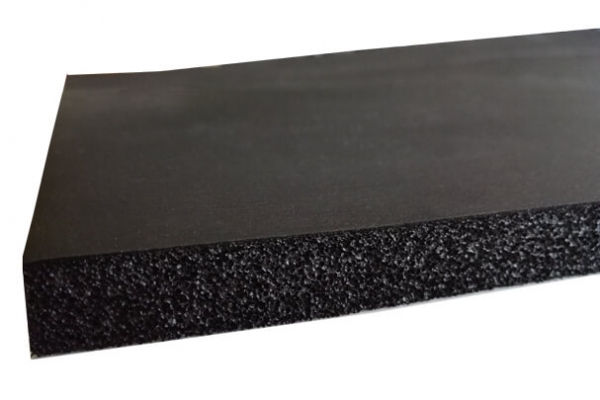

Finishing and Appearance. The real PVC Nitrile foam have a very smooth, even and soft outer skin on one side or on both sides (for foam thickness above 8 mm). Its surface offers a flexible and resilient touch. For the side view, you can clearly find out plenty of clear foamed cells inside the foam sheet. They comes in black color usually, but other colors can also be flexibly customized such as colorful NBR yoga mats.

Foam Sheet Size. The Vinyl Nitrile foam sheets are manufactured originally and finished in rolls with width of 1 meter and length up to 10 meters. Also its thickness can range from 2 mm to 40 mm. As mentioned before, NBR foam with thickness below 8 mm can only have soft skin on one side. Additionally PVC Nitrile foam can be fabricated in both closed cell foam structure and open cell foam structure. But for most applications, closed cell PVC Nitrile foam is the popular and typical choice.

The Finished Products. For foam fabrication, PVC Nitrile foam is easy to work with most of fabrication machinery such steel die-cutting, PSA foam lamination, vertical sawing and custom pad printing. Through all these fabrication processes, we have the capabilities to turn PVC NBR foam into Nitrile foam tape, foam seals, foam gaskets, foam sealing strips, printed foam mats, foam seat cushions and so on.

Specifications and Properties – Closed Cell Nitrile Foam Sheet:

* Size in roll sheet with maximum length 10 m x maximum width 1 m x thickness ranging from 2 mm to 8 mm and custom sizes available.

* General color is black and other colors can be flexibly customized according to customer requirements.

* Foam Density ranging from 70 – 90 kg/m³

* Made of highly resilient PVC and Nitrile rubber materials, Vinyl Nitrile foam can deliver excellent cushioning and shock absorption.

* With closed cell structure, PVC Nitrile foam also have superior performance on thermal and acoustic insulation.

* As soft and flexible closed cell foam material, resilient PVC Nitrile foam can be easily used for uneven surface and create ideal sealing.

* Vinyl Nitrile foam are also excellent at resistance to abrasion, water, weathering and oil etc..

PVC Nitrile Foam Usage and Products:

NBR Foam Gaskets, Seals and Strips

PVC NBR foam sheet has outstanding sealing and insulation abilities. They can also easily be fabricated to NBR foam gaskets, foam seals and foam weathering strips which widely used for construction and building, automotive and other industrial applications.

Nitrile Foam Tape

As Vinyl Nitrile foam has so many good physical properties, they are quite suitable to be manufactured as foam tape with or without adhesive backing. By utilizing our high efficient automated slitter, we have the capability to process PVC/ Nitrile foam tape in various custom sizes.

NBR Foam Tube/ Pipe

Due to its low thermal conductivity property, PVC Nitrile Foam materials are also frequently manufactured as foam tubes serving for HVAC system, industrial pipe lines and other industrial thermal insulation and energy saving applications.

Nitrile Foam Sheet with or without Aluminum Foil

To enhance durability, insulation and energy saving abilities, PVC Nitrile foam can even be laminated with aluminum foil. After added aluminum foil backing, Vinyl Nitrile foam can outperform other foam materials on thermal insulation and sound dampening occasions.

Egg Crate Convoluted Nitrile Foam Sheet

Besides, NBR foam sheet can also be convoluted into egg crate convoluted Nitrile foam just like polyurethane foam. The convoluted Nitrile foam can be powerful sound barriers and present superior acoustic insulation and fire retardance performance for lots of application including acoustic conference rooms, theaters and required testing rooms etc..

NBR Yoga Mats and Seat Cushions

NBR foam sheets can also used to make yoga mats and they are available in various colors including red, blue, green and so on. We do utilize Nitrile foam materials to manufacture seat cushion which can be soft and resilient. Besides, NBR foam is easily to be printed with various custom designs by using basic screen printing.

Typical Applications and Industries:

Construction and Building

Sound dampening

Industrial Thermal Insulation

HAVC Systems

Automotive Seals and Gaskets

Soundproof Applications

Cushion Sports Accessory

Customer Cases – Custom PVC Nitrile Foam Gasket with Adhesive

Here is the black closed cell PVC Nitrile foam gasket we manufactured. It is used as sealing insulation and cushioning for automotive parts.

The NBR foam gasket has thickness of 10 mm with outer skins on both sides. We use die cutting machinery to achieve the custom oval shape design. The PVC NBR foam gasket can provide flexible cushion, sealing and vibration absorption for automotive parts. Also the Nitrile foam gasket has self-adhesive backing and can be much easy to install. It is fabricated by our high efficient foam die cutting machinery with tight tolerance. We also utilized high quality acrylic adhesive backing with white release liner, which can provide sturdy long term adhesive force.

NBR & EPDM

What is NBR and what are the applications?

NBR stands for Nitrile Butadiene Rubber. It is a synthetic rubber copolymer of acrylonitrile and butadiene. The strength of NBR lies in its moderate costs, and good resistance to swelling caused by hydrocarbons or acids. These features ensure that NBR is a cost-efficient and flexible all-round lining material fulfilling the needs of most industrial water applications. NBR is one of the most widely used elastomer in the sealing application. The oil resistance characteristic makes it an ideal material for gasket, roll covers, hydraulic hoses, conveyor belting, oil field packers, and seals for all kinds of plumbing and appliance applications. This material is also ideal for aeronautical material as its operating temperature ranges from -40 °F to 226 °F. Other common uses of NBR include molded goods, footwear, adhesives, sealants, sponges, foams, and floor mats.

What is EPDM and what are the applications?

EPDM stands for Ethylene Propylene Diene Monomer rubber. It is an elastomer which is characterized by a wide range of applications. Performance advantages of EPDM include ozone resistance, excellent electrical insulation, long service life in extreme environmental conditions and sustained flexibility. EPDM rubber is often used in weather seals, and as a source of noise reduction in the automotive industry. EPDM is an excellent source for gaskets or gasket sealing against atmospheric conditions such as sunlight, ozone, wind and rain. EPDM rubber can withstand temperatures ranging from –58°F to 302°F. Due to its resistance to UV (ultra violet rays), ozone, and oxidation, EPDM is used for many outdoor industrial gasket applications for weatherproofing. Also, it is resistant to compression set and atmospheric degradation, it is used in many HVAC (heating, ventilation, and air conditioning) systems and other flexible sealing applications.

CASIS: NBR Foam Sheet Manufacturer and Fabricator

We CASIS is a specialized foam manufacturer and fabricator. Our foam materials include EVA foam, Cross linked Polyethylene foam, PVC/ NBR foam, Neoprene foam rubber etc.. PVC NBR foam is one of the main materials we are working with. They can be highly customized by us to be NBR foam sheets, strips, tapes, gaskets and pads. Also CASIS work closely with customers for best custom solutions on various applications when using PVC Nitrile foam.

For more information, please leave any comments here or contact us.

The NBR foam gasket has thickness of 10 mm with outer skins on both sides. We use die cutting machinery to achieve the custom oval shape design. The PVC NBR foam gasket can provide flexible cushion, sealing and vibration absorption for automotive parts. Also the Nitrile foam gasket has self-adhesive backing and can be much easy to install. It is fabricated by our high efficient foam cutting machinery with tight tolerance. We also utilized high quality acrylic adhesive backing with white release liner, which can provide sturdy long term adhesive force.

NBR & EPDM

What is NBR and what are the applications?

NBR stands for Nitrile Butadiene Rubber. It is a synthetic rubber copolymer of acrylonitrile and butadiene. The strength of NBR lies in its moderate costs, and good resistance to swelling caused by hydrocarbons or acids. These features ensure that NBR is a cost-efficient and flexible all-round lining material fulfilling the needs of most industrial water applications. NBR is one of the most widely used elastomer in the sealing application. The oil resistance characteristic makes it an ideal material for gasket, roll covers, hydraulic hoses, conveyor belting, oil field packers, and seals for all kinds of plumbing and appliance applications. This material is also ideal for aeronautical material as its operating temperature ranges from -40 °F to 226 °F. Other common uses of NBR include molded goods, footwear, adhesives, sealants, sponges, foams, and floor mats.

What is EPDM and what are the applications?

EPDM stands for Ethylene Propylene Diene Monomer rubber. It is an elastomer which is characterized by a wide range of applications. Performance advantages of EPDM include ozone resistance, excellent electrical insulation, long service life in extreme environmental conditions and sustained flexibility. EPDM rubber is often used in weather seals, and as a source of noise reduction in the automotive industry. EPDM is an excellent source for gaskets or gasket sealing against atmospheric conditions such as sunlight, ozone, wind and rain. EPDM rubber can withstand temperatures ranging from –58°F to 302°F. Due to its resistance to UV (ultra violet rays), ozone, and oxidation, EPDM is used for many outdoor industrial gasket applications for weatherproofing. Also, it is resistant to compression set and atmospheric degradation, it is used in many HVAC (heating, ventilation, and air conditioning) systems and other flexible sealing applications.

CASIS: NBR Foam Sheet Manufacturer and Fabricator

We CASIS is a specialized foam manufacturer and fabricator. Our foam materials include EVA foam, Cross linked Polyethylene foam, PVC/ NBR foam, Neoprene foam rubber etc.. PVC NBR foam is one of the main materials we are working with. They can be highly customized by us to be NBR foam sheets, strips, tapes, gaskets and pads. Also CASIS work closely with customers for best custom solutions on various applications when using PVC Nitrile foam.

For more information, please leave any comments here or contact us.